i-Series Integrated HPLC and UHPLC Systems - Features

High Performance Liquid Chromatograph

Innovative i-Series

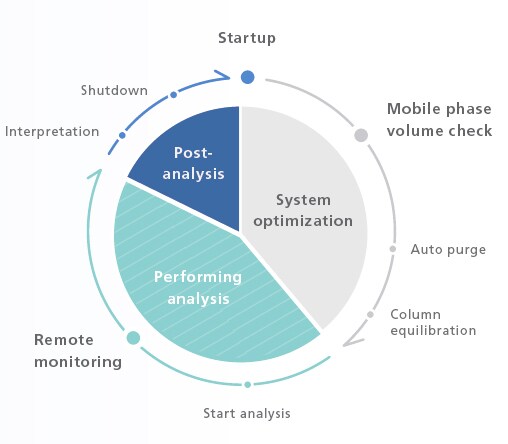

Automation and Remote Operation/Monitoring Encourage a New Style of Work

Analytical Intelligence functions, such as FlowPilot and mobile phase monitoring, and LabSolutions™ Direct can provide an automated workflow together with remote operation and monitoring from instrument startup to analysis completion.

Automated workflows incorporate the work-style habits of experienced analysts. The result is reliable data collected over extended periods.

Using Networks for More Improvements in Work Efficiency

LabSolutions allows remote operation and monitoring of all instruments on the analytical network from any locations, even from home. Analysis data and reports are managed on a centralized database where administrative authorization allows managers to assign appropriate operational restrictions to operators, depending on their expertise and rank.

Mobile Phase Monitoring

Advanced Real-Time Mobile Phase Monitoring

Making sure you have sufficient mobile phase in the system—before batch analysis—is critical to keeping your lab running smoothly. If you run out of mobile phase mid-batch, you have to stop the batch and take corrective action, resulting in costly workflow delays and potential loss of samples.

To overcome this challenge, the Mobile Phase Monitor enables real-time, gravimetric monitoring of mobile phase levels to ensure maximum uptime. Levels for mobile phase or autosampler rinse solution may be monitored in up to six containers. A large bottle version is also available. The containers can also be checked remotely from a smart device (PC/iOS/Android).

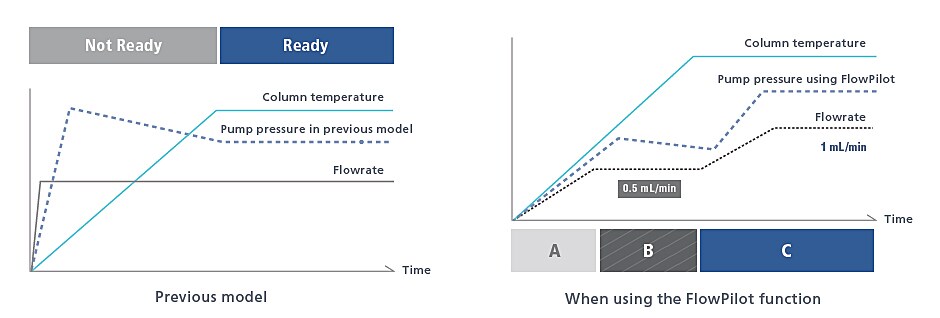

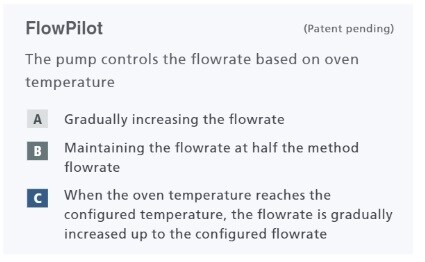

Mobile Phase Flowrate Control Function

Smart Flow Control Protects Columns

UHPLC columns can be damaged by sudden pump starts and extreme gradient changes, especially true with polymeric packings. Smart Flow Control (FlowPilot) increases the flow rate gradually to the method set point according to the status of the column oven, extending the life of your columns.

Remote Operation/Monitoring Function

Take Control of Instruments from Outside the Laboratory

Using LabSolutions Direct, analysts can operate instruments remotely and implement pre-configured methods and batch analyses using the web browser of a computer or a smart device. Instrument status and chromatograms can also be monitored remotely to reduce the time and labor required to travel to and from the laboratory for improved work efficiency.

Intelligent i-Series

Analytical Intelligence is not limited to automating an analytical workflow or remote operations. By aggregating and automating the knowledge and skills of experienced analysts, Analytical Intelligence enables anyone to obtain reliable data and analytical results. Analytical Intelligence is also designed for high levels of compatibility with other instruments and comes with a method migration function, thereby providing an environment where anyone is equally able to obtain data without the need for complex procedures related to data compatibility between different systems.

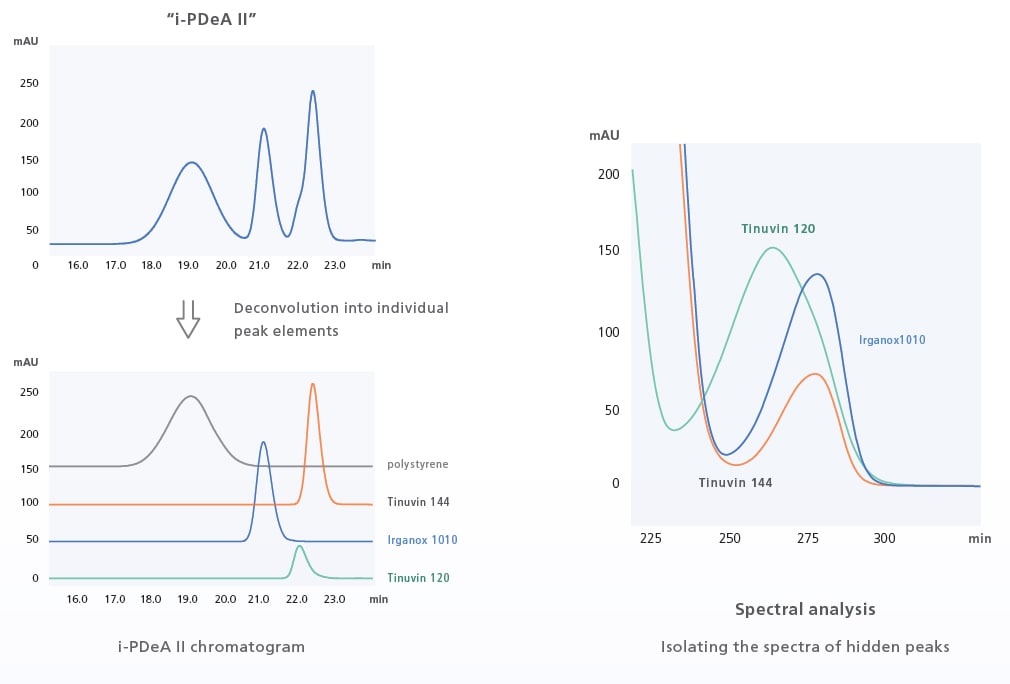

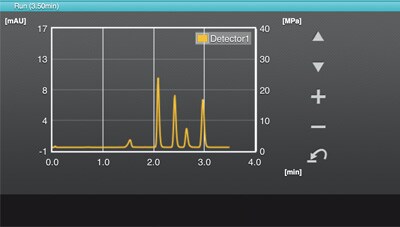

Intelligent Peak Deconvolution with i-PDeA II

Tools to Help in Dealing with Difficult Separations

Achieving baseline separation of LC target components can be difficult and time-consuming, co-eluting peaks are common.

i-PDeA II makes the deconvolution of peaks simple and automatic. The result is a virtual separation that can be used for quantitative determinations.

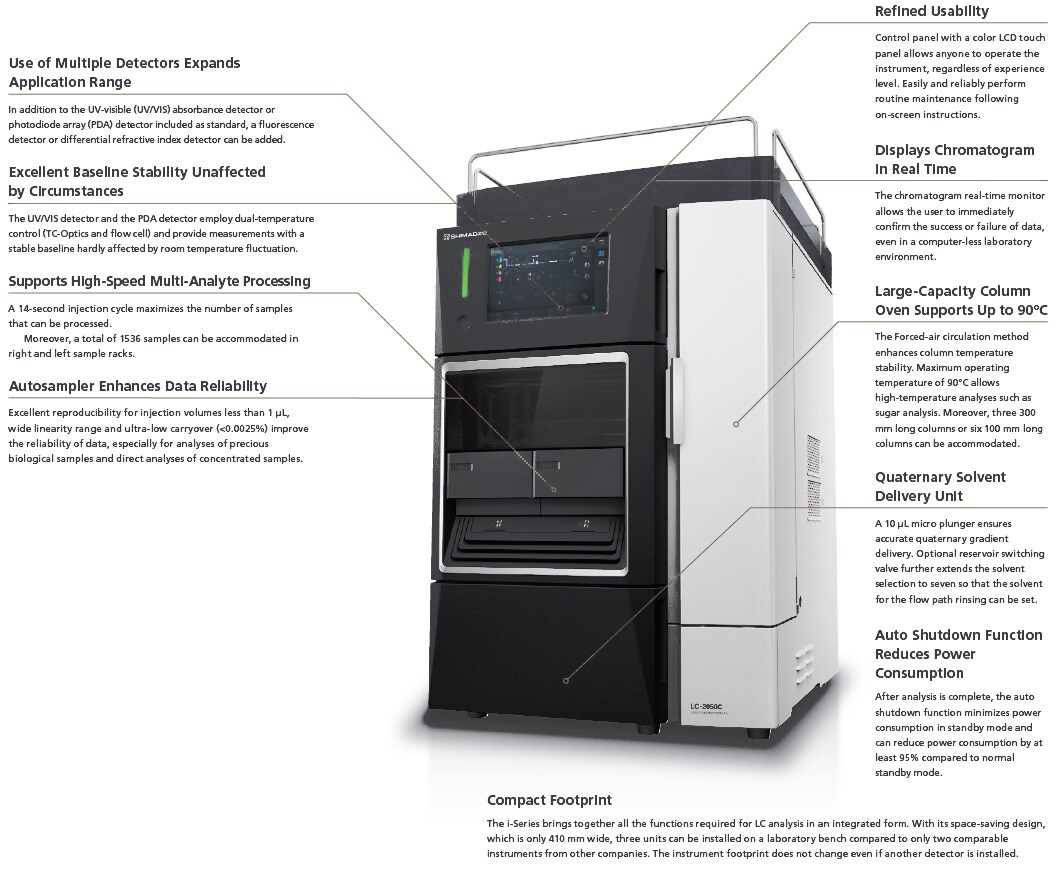

Intuitive i-Series

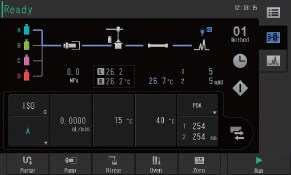

User Interface

Simple in Operation

The user interface replicates the system flow channel and is used to visually check the operating status of the system. Method editing can also be performed from the same screen. With its intuitive design, even users who are completely new to liquid chromatography can navigate the user interface with minimal training.

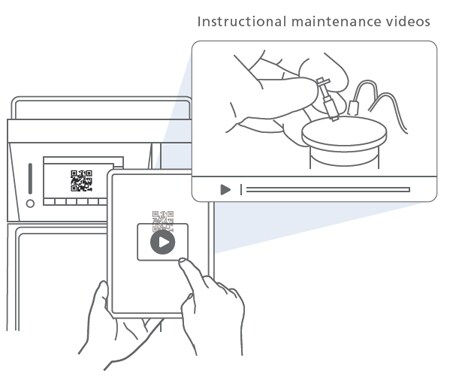

Maintenance Videos

Supporting the Replacement of Consumables

Reading a QR Code® shown on the touch panel directs the user to a website with instructional videos on maintenance. This feature helps improve system availability and increases efficiency.

Auto-Validation Function

Stable Operation Assured with Smart System Startup

An auto-validation function means anyone can follow a set procedure and verify the instrument condition easily. The auto-validation function examines solvent delivery stability, wavelength accuracy, absorbance accuracy, gradient accuracy, the presence of any drift/noise, and other parameters. Also, an instrument check function automatically carries out the routine inspections performed before instrument operation and creates a report showing system self-diagnostic results along with a record of consumables usage, including total solvent volume delivered by the delivery pump, total number of injections performed by the autosampler, and the number of hours the lamp has been illuminated. The system check function also manages auto-validation results, making it easy to accurately determine the operating status of the instrument.

Starting Auto-validation

Procedures, mobile phases, and other information necessary for validation are displayed on the screen, allowing you to perform inspections by simply following the instructions.

Creating a System Check Report

Validation results can be viewed from the i-Series main unit. Validation results can also be output in a report format from a workstation.

Open Access Sample Placement

A direct access mechanism on sample racks allows the user to place the sample on racks that are not involved in sample injection even during analysis. Furthermore, racks can be shared by multiple analysts, without interrupting the analysis of samples placed by others. Overall, this function enhances work efficiency.

Window on a Smartphone

System Monitoring via Smart Devices

System status and chromatograms can be viewed remotely from smart devices and home computers. Situations can be checked without needing to visit the laboratory.

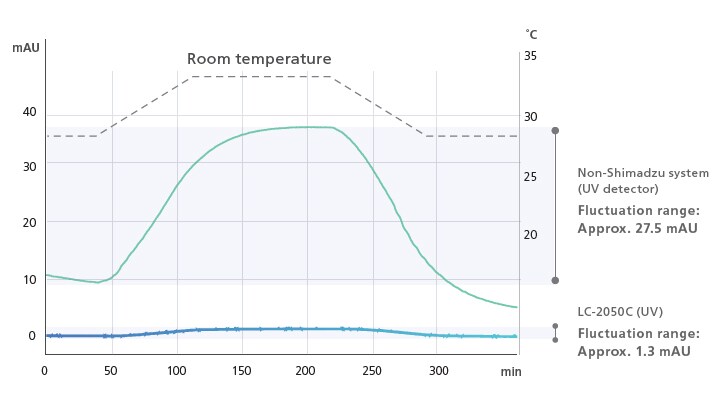

Dual-Temperature Control with TC-Optics and Flow Cells

Excellent Baseline Stability

In addition to the temperature control function for flow cells, the i-Series employs new temperature control technology for detector optical systems, known as TC-Optics (Temperature Controlled Optics). This ensures a more stable baseline that is less susceptible to room temperature variation and increased precision during verification testing and quantitative testing of trace components.

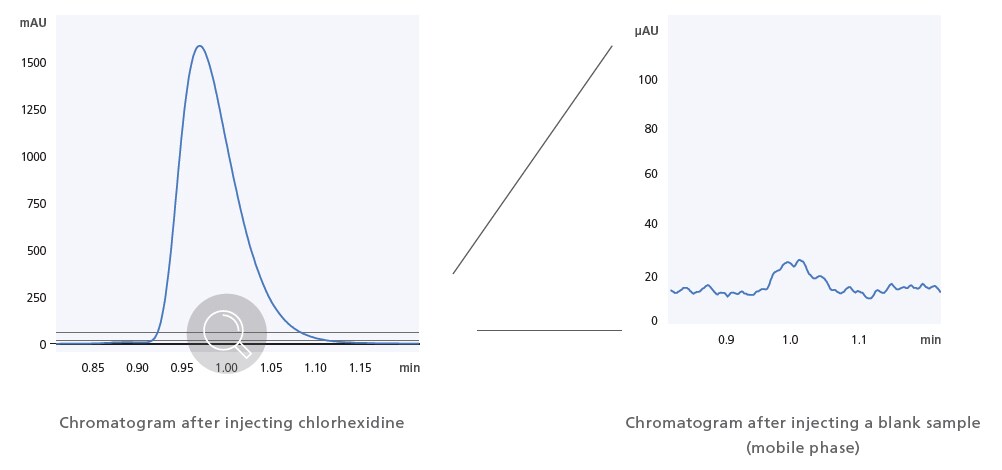

Ultra-Low Carryover Performance Enables High-Sensitivity Analysis

Improved Reliability of Trace Component Analysis

Shimadzu’s proprietary flow channel design, parts, and materials reduce the carryover effects of sample residue to almost zero. Ultra-low carryover performance has been improved to 0.0025% (chlorhexidine, assigned conditions), thereby providing highly precise quantitative performance when analyzing complex samples.