Lubricant Analysis

Engine lubricants play an important role in lubrication, cooling, cleaning, and rust prevention for vehicles, construction machinery, ships, airplanes, and other equipment with internal combustion or turbine engines. As the lubricant deteriorates through use, its performance will decline and the inside of the engine can wear, leading to a decrease in service life and potential malfunction.

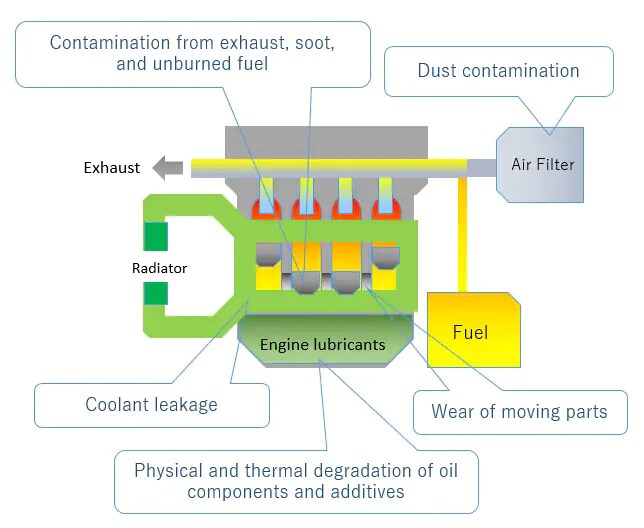

Lubricants deteriorate due to decomposition and chemical changes of oil components and additives caused by physical and thermal stresses, as well as contamination by metal wear particles and incorporated fuel. Therefore, it is recommended to analyze the lubricant throughout its lifespan to assess its quality, utility, and remaining service life. These analyses can be accomplished with a number of instruments.

Typical causes of engine lubricant deterioration

Analytical Techniques

Examples of ASTM Lubricant Analysis Methods

| Analysis items (Elements) | Needed system | Standards | |

|---|---|---|---|

| Deterioration | Oxidation | FT-IR | ASTM E2412 |

| Nitration | |||

| Sulfate by-products | |||

| Contamination | Water | FT-IR | ASTM E2412 |

| Soot | |||

| Gasoline | GC | ASTM D3525 ASTM D7593 |

|

| FT-IR | ASTM E2412 | ||

| Diesel | GC | ASTM D3525 ASTM D7593 |

|

| FT-IR | ASTM E2412 | ||

| Coolant (B, Na, K) | ICP-AES | ASTM D5185 | |

| FT-IR | ASTM E2412 | ||

| Antifreeze (Na) | ICP-AES | ASTM D5185 | |

| Dust (Si) | |||

| Seal materials (Si) | |||

| Wear | Metals (Al, Fe, Cu, Cr, Ni, Zn, etc.) | ICP-AES | ASTM D5185 |

| Additives | Anti-oxidant (Zn, Cu, B) | ICP-AES | ASTM D4951 |

| FT-IR | ASTM E2412 | ||

| Anti-wear agents (B, Cu, K, S, Zn, etc.) | ICP-AES | ASTM D4951 | |

| FT-IR | ASTM E2412 | ||

| Detergent inhibitors (Ba, Mg, Ca, etc.) | ICP-AES | ASTM D4951 | |

| Corrosion inhibitors (Ba, Zn) | |||

| Anti-rusting agents (K, Ba) | |||

| Friction modifier additives (Mo) | |||

Lubricant Deterioration Analysis Using Compact FT-IR

FTIR Spectrophotometer

Applicable Method

Condition Monitoring of Lubricant oil (ASTM E2412/D7418/D7414/D7415/D7412)

Rapid Analysis of Fuel Dilution of Engine Lubricants by GC

Gas Chromatography

Applicable Method

Fuel dilution analysis of engine lubricants (ASTM D3524/D3525/D7593)

Analysis of Additive Elements, Wear Metals, and Contaminants in Used Lubricants using ICP-AES

ICP Emission Spectrometer

Applicable Method

Elements analysis in Lubricating oil (ASTM D4951/D5184 )