Thin Films/Coatings Materials Testing

Testing, Analysis and Inspection of Thin Films and Coatings

The development of high-performance thin films and coatings is critical to many traditional and advanced technologies. Examples include: new environmentally friendly paints, the thin-film optics used in cell phone cameras, anti-reflective coatings on solar panels and protective diamond-like-carbon films used in automotive parts.

Shimadzu instruments are used by researchers world-wide to characterize the composition, mechanical and optical properties of a wide range of thin-films, paints and coatings.

Below are a few examples:

Featured Applications

Ultra-high-speed Imaging of Laser Ablation Processes

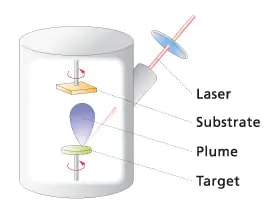

Laser Ablation is an important thin film deposition process. Laser light is used to ablate material from a target which deposits onto a substrate to form a thin film. Researchers at the Tanabe Laboratory at Kyoto University have used a Shimadzu HPV series camera to capture images of the laser light impacting targets at 10 million frames per second.

Provided by the Tanabe Laboratory at Kyoto University

Recording speed: 10 million frames/second

Width of field of view: Approx. 50 mm

Laser Ablation Deposition System

Mechanical Strength Evaluation of Functional Film Used in Smartphones

Plastic film is formed into thin film using techniques such as extrusion and stretch molding of the polymer film. A wide variety of products having special characteristics, such as water retentivity, light reflectivity, and selective permeability for specific substances, can be found all around us as industrial products, construction materials, everyday necessities, etc. This paper introduces an example of the strength evaluation of self-repair coating film used on the functional protective film that covers the LCD screens of such products as smartphones and tablets.

Determination of Volatile Organic Compounds in Water-based Paints and Varnishes Using GC-MS

Water-based paint has been increasingly gaining popularity in the recent years for some of its advantages. Most probably the biggest advantage of water-based paint is that it does not pervade the room with the strong smell that solvent-based paint does. Volatile organic compounds (VOCs) are responsible for the signature smell in paints, and are considered to be harmful to the environment. Using GC-MS it’s possible to determine the amount of VOCs in water-based paints and varnishes.

Evaluation of Hardness of Painted Surfaces

The hardness test of painted surfaces is most important in evaluation of the quality of the paint film. Surface hardness of paint differs depending on the kind of paint and method of drying. Information about the hardness near the surface can be obtained using the Dynamic Ultra Micro Hardness Tester from Shimadzu.

Measuring of Coating Additives

There are a number of ways of analyzing paint scrapings employing the FTIR. The use of an infrared microscope allows the determination of the main components of the individual layers of paint.

Analysis of Paint Scrapings Using an Infrared Microscope

Using an ultrasonic fatigue testing system equipped with an average stress loading mechanism, gigacycle fatigue test can be performed with an average tensile stress loaded. The industries unique USF-2000A Very High Cycle Fatigue testing system reduces fatigue life tests from years to days or even hours.

Pass/Fail Judgment of Automotive Window Tint Film Using the Spectral Evaluation Function of LabSolutions UV-Vis Software

In this article we performed measurement of automotive window tint film using the spectral evaluation function of LabSolutions UV-Vis software. This example demonstrates the effectiveness of using the spectral evaluation function of LabSolutions UV-Vis software to make a pass/fail judgment easily. The use of this function reduces the effort required to obtain pass/fail judgments from measurements and enables various quality inspections with great efficiency.