Greenhouse Gas Analysis

Development and Application of Automated Simultaneous Analyzer for Three Greenhouse Gases

INDUSTRY

KEYWORD

Climate change, green gas, CO2, CH4, N2O

INTRODUCTION SERVICE&PRODUCTS

Greenhouse Gas Analysis, GC-2014 Gas Chromatograph , AOC-6000 Plus

The three main greenhouse gases that contribute to climate change are carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O). Emissions of carbon dioxide are the largest source, followed by methane. The global warming potential (GWP) of methane is more than 20 times that of carbon dioxide, and countermeasures to mitigate it are necessary. At the 2021 United Nations Climate Change Conference (COP26) held last November, more than 100 countries and regions launched their participation in the Global Methane Pledge to reduce global methane emissions by 30% from fiscal 2020 levels by 2030. It is said that the world's largest source of methane emissions comes from livestock, such as enteric frementation, but in Japan, the largest source of methane is rice paddy cultivation.

In this interview, we interviewed with Dr. Shigeto Sudo of the National Agriculture and Food Research Organization (NARO), who is studying mitigation options for paddy fields. Dr. Sudo developed an analyzer that can automatically and simultaneously analyze three components of greenhouse gases (CO2, CH4, N2O).

Shigeto Sudo

Group Leader

Institute for Agro-Environmental Sciences

Division of Climate Change Mitigation Research

Mitigation System Group

*Affiliates and titles of the interviewee are current as of the time of reporting.

National Agriculture and Food Research Organization

I majored in chemistry when I was an undergraduate student, but when I entered graduate school in 1990, I specialized in atmospheric chemistry, researching the causes of the ozone hole, which was a major environmental issue at that time. I started using Shimadzu's GC-14A equipped with electron capture detector (ECD) when I was working on an analytical method to analyze the concentration of N2O from bubbles in Antarctic ice core samples as a dating method for N2O. Since the theme of my doctoral thesis was related to both methyl bromide, a soil fumigant used in agriculture, and N2O, a major agricultural emission, NARO, to which I am now affiliated, approached me with a job offer.

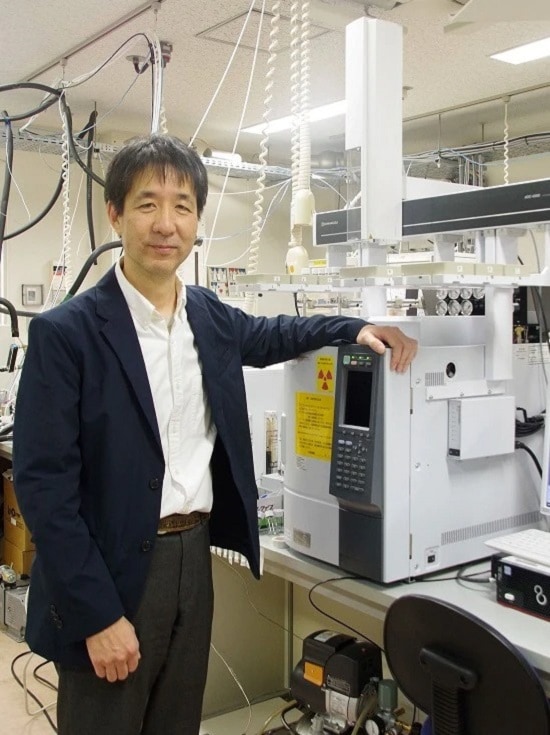

Automated three-greenhouse-gas analyzer, Unit 2

I started to develop an automated simultaneous analyzer for three greenhouse gases (CO2, CH4, N2O) (referred to below as an automated three-greenhouse-gas analyzer) in 1999, the year I was appointed to my job. I spent five years to emanate the idea and about six more months to assemble the system. The first unit (Unit 1) was completed by combining two gas chromatographs (GC-14B). The problem of global warming became more serious during the five years completing the project, and it became necessary to measure a larger number of samples, so in the latter half of 2005, we completed the second unit (Unit 2), an improved version with a headspace sampler (HSS-2B). The path to the completion of Unit 1 was difficult because it was all done by hand. However, after Unit 1 was complete, we applied for a patent and asked Shimadzu Corporation to produce Unit 2 as a custom-built special order.

Automated three-greenhouse-gas analyzer, Unit 2

The automated three-greenhouse-gas analyzer enables the measurement of CO2, CH4 and N2O in a single sample injection. As a result, analysis errors were reduced, processing speed was increased, and running costs were significantly reduced by using a common carrier gas.

After the automatic gas sampler was changed to an AOC-5000 on Unit 3, two major reforms were adopted for Unit 4, which was completed in 2019. First, we changed the carrier gas from helium to nitrogen. Helium, which we had previously used, has been difficult to obtain since 2010 due to supply shortage. This change was not straightforward and required two years. Second, we reduced the number of gas chromatographs from two to one while keeping the same functionality. In addition to making the system more compact, this also reduced costs.

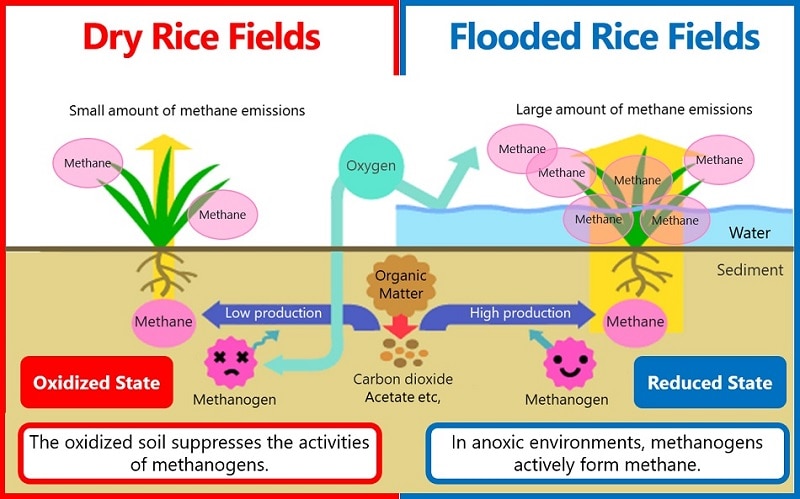

The major source of methane emissions in Japan is rice cultivation. In order to reduce methane, whose global warming potential is more than 20 times that of carbon dioxide, it is vital to control the generation of methane from the paddy fields that cultivate rice, the staple food of the Japanese people.

Although there are regional differences in the timing of methane generation from paddy fields, the activity of methanogens increases when there is water in paddy fields from mid to late June when new stems emerge from the original stem.

Then, around August, the rice plants act as straw and release large amounts of methane into the atmosphere. To suppress the activity of methanogens and reduce methane generation, we found that the rice cultivation methods of adjusting the growth of the rice by draining water from paddy fields about 1 or 2 weeks of mid-season to keep roots healthy and extending the midterm drying period were effective.

A manual published by NARO in 2012 to serve as a reference for the study of rice cultivation is issued to farmers and local governments.

Mechanism of greenhouse gas emissions from agriculture (Source: NARO)

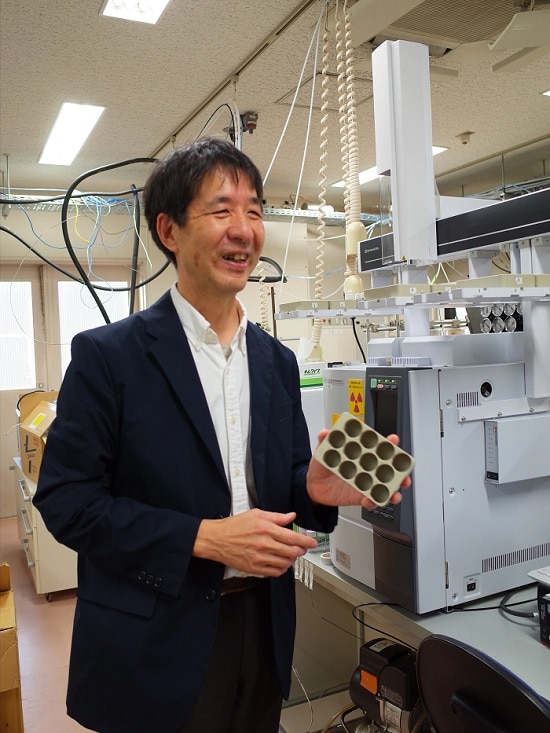

Greenhouse gas generation control facility at NARO

One of the most important tasks in preparing this manual was to identify changes in the concentration of greenhouse gases. To do this, we utilized the automated three-greenhouse-gas analyzer, which automates the measurement process from gas sampling to injection. The development of this system, which offers rapid and highly accurate analysis technology, has contributed to the suppression of methane generation in Japan. We have also demonstrated the system in India and Southeast Asia, where rice cultivation is also practiced. We hope to use this method to mitigate methane emissions in rice cultivation not only in Japan but also in the rest of the world.

I have used Shimadzu's analytical instruments for a long time and have a good grasp of their features. Also, I think the design and support are excellent, with parts that are reasonable and easy to obtain and systems that are ready to customize. When I first started to develop the automated three-greenhouse-gas analyzer, I built Unit 1 by myself. Since Unit 2, Shimazu's service department has responded well to our requests, and now they are in the process of building Unit 5.

No one trusted this system when it was first developed. But since the release of Unit 4, Shimadzu Corporation has collaborated with us to develop and commercialize the system, and the product is now being used in a variety of places. The system has advantages in terms of analysis speed, accuracy, and running cost, and we hope that it will be used more widely in the future for data collection in greenhouse gas analysis.

It is very important to understand greenhouse gases in order to solve climate change problems. I have been working on this research for 20 years with the idea that Japan should take the initiative in analytical technology. I hope Shimadzu will continue to play an active role in the world with its expertise in analysis to combat global warming.

Many Shimadzu products such as gas chromatographs are used in your laboratory besides the automated three-greenhouse-gas analyzer Unit 1-4. We will continue to develop products to make further contributions. Thank you very much for your valuable talk today.