Advanced Flow Technology Series - Features

Advanced Flow Technology Series

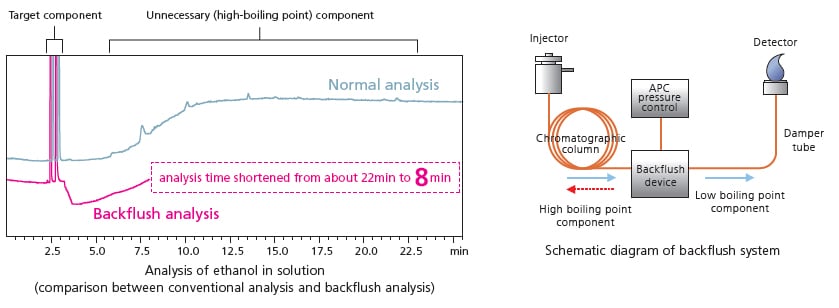

Backflush system

The backflush system reverses the carrier gas flow after the target compounds have eluted, to discharge residual late eluting compounds in the column through the injection port split vent, thus shortening the analysis time and improving productivity. In addition, high-boiling point components are discharged efficiently to reduce the bakeout time and thus prevent column deterioration, contamination and retention time shifts.

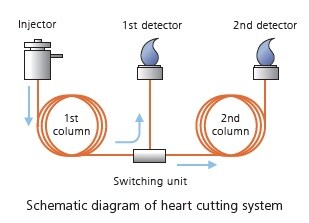

Heart cutting system

The heart cutting system uses two chromatographic columns with different separation characteristics to separate specific compounds from complex original samples for quantitation. It can achieve high separation analysis which cannot be achieved

by single chromatographic column.

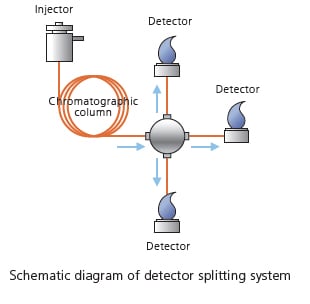

Detector splitting system

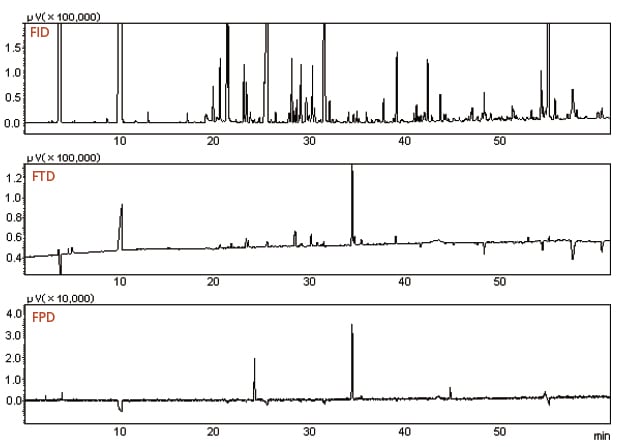

Compounds eluting from an analytical column may be split into multiple detectors to obtain multiple chromatograms. Offering abundant information in a single analysis, this system saves time and money and improves productivity. The combination of a common detector and selective detector can improve the analysis accuracy and support the analysis of complex samples with more impurities.

Simultaneous analysis of grapeseed oil with detector splitting system (FID, FTD, FPD)

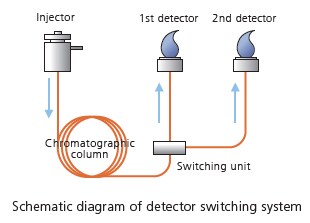

Detector switching system

The detector switching system controls sample introduction through the switching device at the column outlet. Unlike the detector splitting system, the detector switching system can distribute the chromatographic column fractions to different detectors.

Multi Dimensional Gas Chromatograph Systems

MDGC/GCMS Series

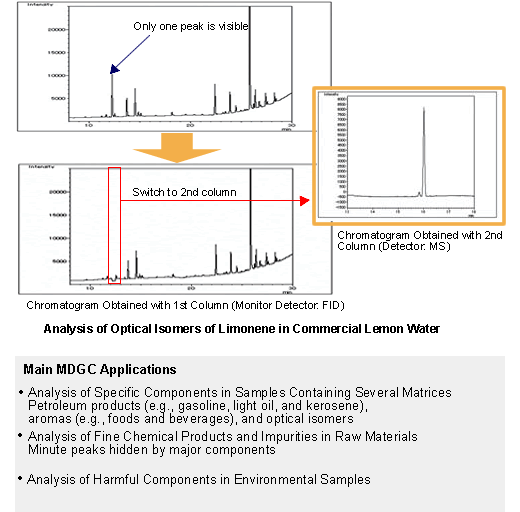

The complete separation and quantification of specific compounds can be difficult in samples that contain many compounds, such as petroleum products and fragrance products. Multi-Dimensional GC (MDGC) uses columns with different separation characteristics to achieve highly accurate separation of target components from such complex matrices.

Multi-Dimensional GC/GCMS System

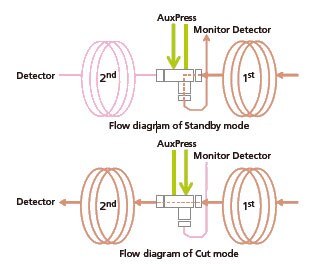

The multi-dimensional GC/GCMS system uses two columns with different separation characteristics to achieve high-resolution analysis not possible with a conventional single column. Components insufficiently separated as they pass through the first column (1st column) are introduced ("heart-cut") into a second column of a different type (2nd column) to separate their analytes.

Outstanding retention time stability

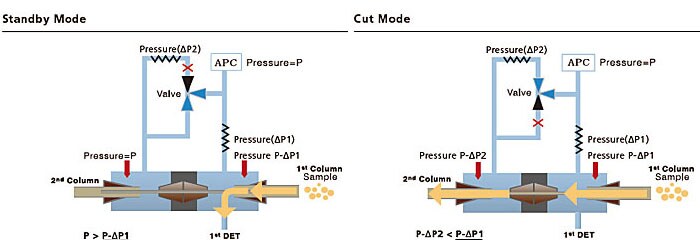

Multi-Deans Switching

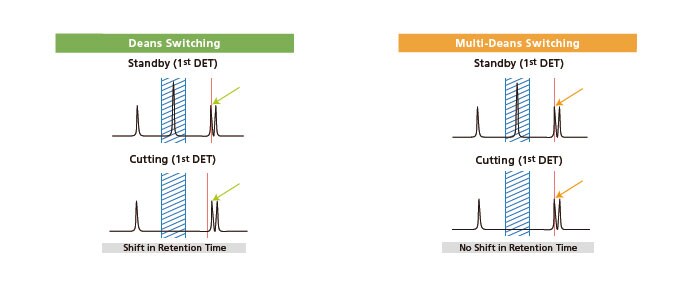

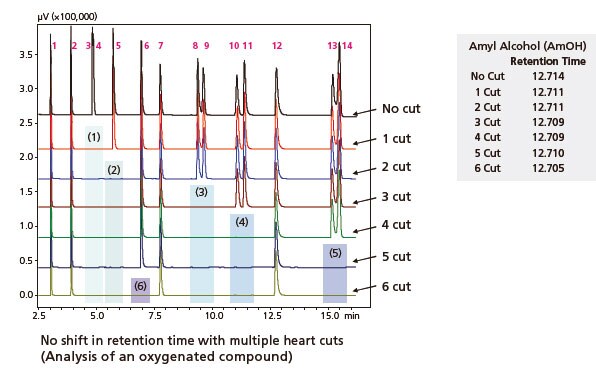

In the past, samples have been introduced to columns using the switching mechanism known as Deans-switching. However, this system results in such problems as a reduced recovery rate and fluctuations in the retention time.

The MDGC/GCMS Series system incorporates multi-Deans switching, a new mechanism that significantly reduces the likelihood of fluctuations in the retention times of eluted components, even if switching is performed several times.

Superior Intuitive Operability

MDGC Analysis Conditions Display Window

MDGCsolution Software

MDGC Analysis Conditions Display Window

Using the "MDGCsolution" MDGC control software, the flow rate conditions for both columns and the switching program can be set simply with mouse operations while viewing the chromatogram obtained with the 1st column.

Excellent Peak Picking Capability

One important feature of MDGCsolution is that it allows the switching settings to be performed while viewing the chromatogram. If you move the cursor near a peak to be heart-cut on the chromatogram and double-click, the switching is set in units of 0.01 minutes. Because operation is this simple, hardly any time is required when performing multiple switching or when creating multiple methods with different switching timings. It is also possible to create a method during analysis using the Offline Editor menus.

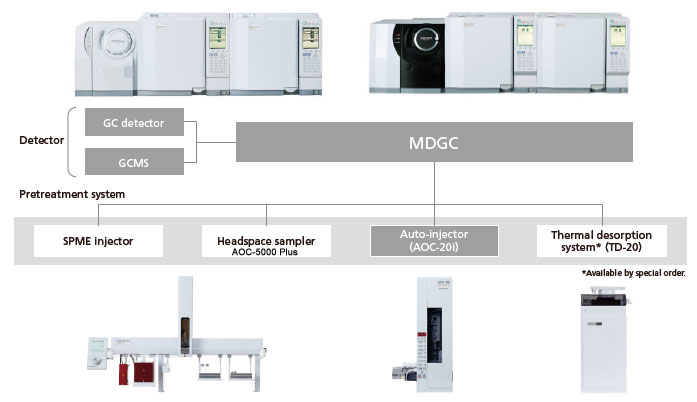

A Wide Variety of Optional Systems

In addition to GCMS, various other detectors, such as an FID or FPD, can be used with the MDGC/GCMS series. For example, a headspace sampler and thermal desorption system can be connected and controlled as a pretreatment system. When not using the MDGC/GCMS series as an MDGC system, it is possible to use the GC and GCMS components as independent systems by changing the column and detector connections.

Ease of Maintenance

The switching element is located at the top of the front edge of the GC oven. Column replacement and connection to the detector or pretreatment unit are easy. The column connectors contain highly heat-resistant stainless-steel ferrules to eliminate the need for retightening and the danger of seizing associated with conventional Vespel ferrules. Both connection and maintenance are easy.