TCR

TCR

TCL

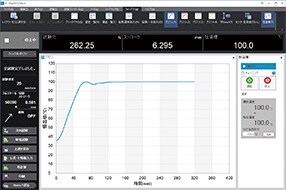

Software Window (TCE-N300A)

Shimadzu Scientific Instruments Launches New AUTOGRAPH AGS-V Series

Shimadzu Scientific Instruments (SSI) introduces the AUTOGRAPH AGS-V Series Tabletop Precision Universal Testing Machines. Featuring a wide selection of load cell capacities, versatile control options and compatible accessories, the AGS-V Series delivers dependable testing of diverse material types.

SAMPE 2025

May 20-21

Indiana Convention Center

Indianapolis, IN

Booth # T12

MD&M West 2025

February 4-6

Anaheim Convention Center

Anaheim, CA

International Elastomer Conference 2024

September 10-12

David L. Lawrence Convention Center

Pittsburgh, Pennsylvania

SAMPE 2024

May 21-22

Long Beach Convention Center

Long Beach, California

Booth # H18

Medical Design & Manufacturing West 2024

February 6-8

Anaheim Convention Center

Anaheim, California

Booth #2283