How do diffraction gratings work?

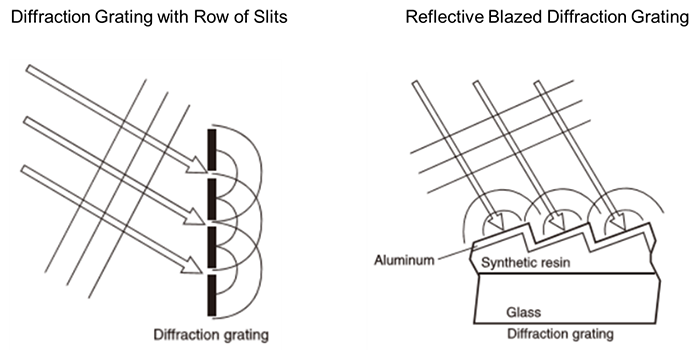

The first diffraction gratings were often a row of slits which functioned as a transmission grating, as shown at left. Modern diffraction gratings are a reflective blazed grating type that has a sawtooth cross-section, as shown at right. As light that passed through an adequately fine slit is diffracted, so light reflected from an adequately fine sawtooth surface is also diffracted. There are 500 to 2000 serrations per millimeter.

In the past, the sawtooth face of a commercially produced diffraction grating is the replica of a master grating. A thin synthetic-resin replica is stuck onto a glass sheet and coated with aluminum. The master was traditionally produced using a machine tool, but now the surface is formed by an ion beam or using laser beam photolithography. This photolithographic process produces gratings with fewer imperfections. This smoother surface reduces stray light (light at unwanted wavelengths) by significant amounts.