AABC (Advanced Automotive Battery Conference) 2025

December 9-11

Caesars Palace

Las Vegas, NV

As the chemical industry has developed, adhesives using synthetic polymers as raw materials have been commercialized. These adhesives are often used in a variety of industrial fields, including electronics and electrical machinery. This article introduces an example of a 90° peeling test for adhesives used in adhesive tapes.

The sample was an ordinary adhesive tape cut to a width of 24 mm and a length of 300 mm; it was set on a SUS304 stainless steel plate. An adhesive tape peeling test attachment, which is capable of peeling off tape at an angle of 90° from the plate on which the sample was set, was used as the test jig.

Fig. 1: Peeling Test

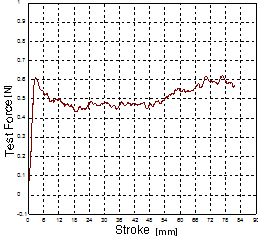

Fig. 2: Relationship between the Test Force and Stroke

The test was implemented at a loading speed of 300 mm/min. After measurement started, measurement values for the initial length of 25 mm were discarded. Afterwards, the adhesive force measurement values for a length of 50 mm peeled off the plate were averaged. This average value was taken as the peeling adhesive force.

Table 1: Result

| Peeling Adhesive Force |

| 0.238 N/10 mm |

Tensile Testing System for Plastic Materials

| Tester | AGS-X |

| Load Cell | 50 N |

| Testing Jig | Adhesive Tape Peeling Test Attachment |

| Software | TRAPEZIUM LITE |