AABC (Advanced Automotive Battery Conference) 2025

December 9-11

Caesars Palace

Las Vegas, NV

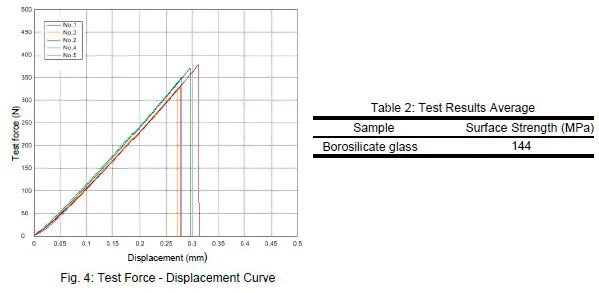

In recent years, there has been an increase in smart phones, tablets and other mobile devices that use glass. Mobile products require the strength to resist bends, drops and other external forces, and any glass pieces must also be sufficiently strong. For glass, there are typically two types of strength, which are measured by different methods. One type is edge strength, which is obtained from 3-point (or 4-point) bending tests. When glass is cut, microscopic damage (microcracks) appears at the cut surface. With a 3-point (or 4-point) bending test, strength is determined by the fracture from these cracks. In other words, edge strength could be called an indicator of the degree of damage at a fracture surface. The other type is surface strength, which is determined from ring bending tests. In this method, fracture starts near the center of the glass, so there is no cut surface impact. In other words, surface strength could be called an indicator of the strength of the glass surface itself. In this article, we introduce an example of a ring bending test, as per the ASTM standard, to obtain the surface strength of glass.

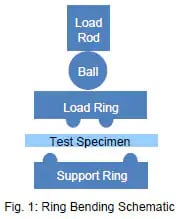

Fig. 1 shows a schematic diagram of the jigs used with the ASTM standard (ASTM C1499-01). This standard includes precise specifications regarding the measurements and jigs, a portion of which are shown below.

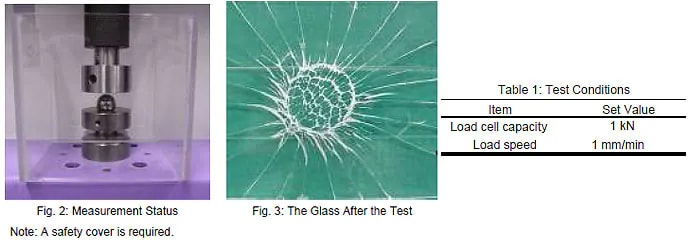

Tester: AGS-X Load Cell: 1 kN

Test Jig: Ring bending test jigs, safety covera

Software: TRAPEZIUM LITE X