AABC (Advanced Automotive Battery Conference) 2025

December 9-11

Caesars Palace

Las Vegas, NV

Specular reflectance measurements are used for an extremely wide range of applications, such as evaluating the performance of materials with low reflectance like antireflective coatings used on lenses and LCDs or evaluating the performance of materials with high reflectance like laser mirrors. Specular reflectance is measured using an absolute reflectance attachment or specular reflectance attachment.

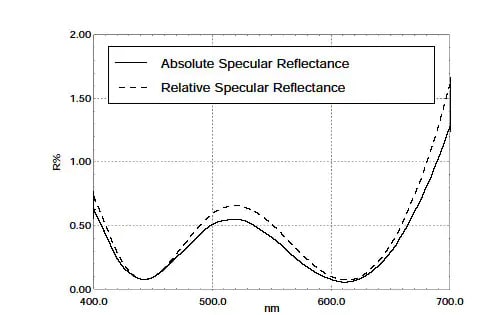

In this example, an eyeglass lens with an antireflective coating was measured using a specular reflectance attachment and an absolute reflectance attachment.

Measurement data from the absolute reflectance attachment (absolute reflectance) are obtained as absolute values, whereas measurement data from the specular reflectance attachment (relative reflectance) are relative values with respect to a reference aluminum reflecting mirror.

The reflectance values of aluminum reflecting mirrors also depend on the wavelength, but are about 80 to 95 % of absolute values. Since the reflectance of the reference mirror is not 100 %, the measurement values will differ from the values from the absolute reflectance attachment. However, if the same reference mirror is always used, measurements can be made with good repeatability.

Eyeglass Lens Measurement Data

A UV-VIS spectrophotometer can conduct reflection and absorption measurements on solid samples (powders, semiconductors, thin films, glass) as well as conventional liquid samples. A double monochromator type (UV-2700i) that ensures low stray light and a wide range and a single monochromator type (UV-2600i) with excellent cost performance are available. Both models incorporate next-generation UVProbe software to achieve sophisticated functionality.