AABC (Advanced Automotive Battery Conference) 2025

December 9-11

Caesars Palace

Las Vegas, NV

Analytical Instruments Used for Hydrogen Fuel Quality Control

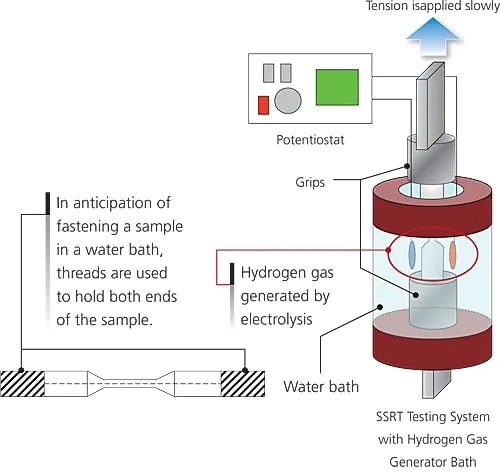

Metal is one tubing material used in hydrogen stations. Due to its exposure to high-pressure hydrogen gas environments, the metal in hydrogen gas tubing must be resistant to hydrogen embrittlement. Therefore, to evaluate hydrogen brittleness, the tensile testing system was designed to test tensile strength at extremely slow speeds in a hydrogen gas environment.

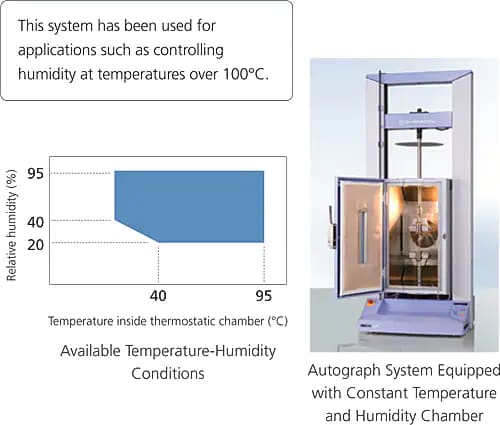

Inside fuel cells, the process of generating electricity increases the temperature, which creates a high-humidity state. Consequently, to develop batteries with a long service life, the physical properties of the electrolyte membrane in fuel cells must be evaluated in a temperature and humidity-controlled environment. Therefore, the system was designed to evaluate strength while controlling the temperature and humidity.

In addition to material development applications, these tests can also be used to establish indices or material selection criteria for designing hydrogen stations and fuel cells.

Examples of Previous Applications

This system is used to perform slow strain-rate tests (SSRT) in a hydrogen gas environment.

It evaluates the effects of hydrogen embrittlement on fuel cell containers and tubing materials.

Examples of Previous Applications

Tensile-testing electrolyte membranes in a simulated fuel cell environment.

In addition to testing to failure in a high temperature and humidity environment, the system is also used to evaluate electrolyte membrane shrinkage when the temperature and humidity are varied under a constant load.