ASTM A615: Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement

ASTM A615 is the standard specification that covers deformed and plain carbon-steel bars used for the reinforcement of concrete. These bars, commonly referred to as "rebar," are a critical component in construction, providing tensile strength to concrete structures, which are otherwise strong in compression but weak in tension. ASTM A615 specifies the mechanical properties, chemical composition, and dimensional requirements for rebar to ensure its suitability for use in structural applications like buildings, bridges, highways, and other concrete constructions.

This webpage provides an overview of ASTM A615, but it is recommended that users refer to the full ASTM A615 standard for complete details on procedures and requirements.

ASTM A615 Properties of Interest

The key mechanical and material properties specified in ASTM A615 include:

Tensile Strength: The maximum stress that the steel rebar can withstand while being stretched or pulled before breaking.

Yield Strength: The stress at which the steel begins to deform plastically and will not return to its original shape. Rebar is classified into different grades (e.g., Grade 40, Grade 60, and Grade 75) based on its yield strength in psi.

Elongation: The amount of permanent stretch the rebar undergoes before breaking, indicating its ductility.

Bend Test Requirements: Ensures the rebar can be bent without cracking, which is essential for forming and shaping during installation in concrete structures.

ASTM A615 Testing Setup and Method

Testing of rebar to meet ASTM A615 is typically performed using specialized equipment, including:

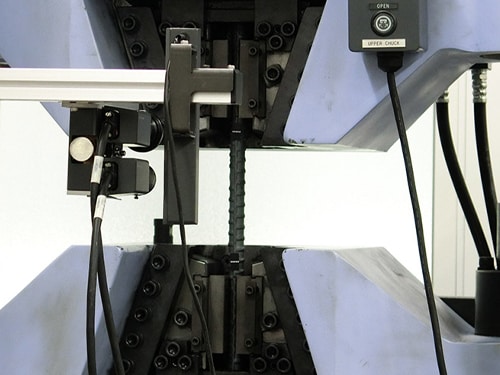

Universal Testing Machine (UTM): Used to measure the tensile strength, yield strength, and elongation of the rebar. The machine must be capable of applying high loads, as rebar is often tested at forces exceeding 100,000 pounds.

Bend Test Fixture: This fixture is used to evaluate the rebar’s ability to withstand bending without cracking, which is essential for concrete reinforcement.

ASTM A615 Software Features

-

The software used for testing rebar to ASTM A615 focuses on precise data acquisition and analysis to ensure compliance with the standard. Key features of the TRAPEZIUMX-V software includes:

Real-time Stress-Strain Curve Plotting: The software captures and displays the stress-strain behavior of the rebar as it is pulled to failure, allowing for quick identification of yield and ultimate tensile strength.

Automatic Calculation of Key Properties: Tensile strength, yield strength, and elongation are calculated automatically, minimizing operator input and reducing the chance of errors.

Data Reporting and Compliance: Generates detailed reports that meet ASTM A615 requirements, including mechanical properties, bend test results, and chemical analysis (if applicable).

-

ASTM A615 Specimen Details

The rebar tested under ASTM A615 is typically sampled directly from production, and the specimen preparation must adhere to specific guidelines:

Size and Diameter: ASTM A615 covers rebar in sizes ranging from No. 3 (10 mm) to No. 18 (57 mm) in diameter. The size affects the required mechanical properties, with larger sizes generally needing to meet lower elongation criteria.

Deformation Pattern: Deformed rebar features ridges or indentations that improve its bonding with concrete. The deformation pattern must meet specified height and spacing requirements to ensure adequate performance in reinforced concrete.

Length: Rebar specimens for tensile testing are typically prepared with a gauge length of 8 inches or 200 mm, depending on the size of the bar.

Surface Condition: The surface must be clean and free of rust, scale, or other imperfections that could affect the accuracy of the tensile or bend test results.