ASTM D882: Standard Test Method for Tensile Properties of Thin Plastic Sheeting

ASTM D882 is the standard test method for determining the tensile properties of thin plastic sheeting, including polyethylene, polypropylene, and other polymer films. This standard provides a means to evaluate the mechanical properties that affect the performance of plastic sheeting in various applications, such as packaging, construction, and automotive industries. The test results yield essential information about the material's strength, elongation, and overall performance under tensile loads.

This webpage provides an overview of ASTM D882, but it is recommended that users refer to the full ASTM D882 standard for complete details on procedures and requirements.

ASTM D882 Properties of Interest

The primary properties measured in ASTM D882 testing include:

Tensile Strength: The maximum stress that the plastic sheet can withstand while being stretched before breaking, typically expressed in pounds per square inch (psi) or megapascals (MPa).

Elongation at Break: The percentage of elongation that occurs at the point of fracture, which indicates the material's ductility and flexibility.

Modulus of Elasticity: The ratio of stress to strain in the elastic region of the material, providing insight into its stiffness.

ASTM D882 Testing Setup and Method

Testing according to ASTM D882 requires specific instruments to ensure accurate results:

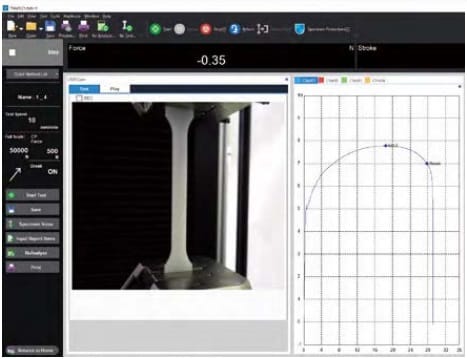

Universal Testing Machine (UTM): Used to apply a controlled tensile force to the plastic sheet samples, measuring the force and elongation during testing.

Extensometers: Attached to the specimens to measure elongation with high precision during the tensile test.

Sample Preparation Tools: Equipment for cutting specimens to the specified dimensions, ensuring uniformity and consistency.

ASTM D882 Software Features

-

The TRAPEZIUMX-V software used for ASTM D882 testing offers several features for data collection and analysis:

Real-time Stress-Strain Curve Plotting: Provides immediate feedback on tensile performance, allowing for quick identification of key properties.

Statistical Analysis and Reporting: Automatically generates comprehensive reports that include key metrics and compliance with specifications.

-

ASTM D882 Specimen Details

Specimens for ASTM D882 testing are typically prepared as follows:

Dimensions: Standard test specimens are usually 1 inch (25 mm) wide and of a specified gauge length, typically 8 inches (200 mm).

Thickness: The thickness of the plastic sheet is specified, as the standard applies to thin materials, usually less than 0.25 inches (6.35 mm).

Surface Condition: Specimens should be free from defects such as wrinkles, holes, or other irregularities that may affect test results.