AABC (Advanced Automotive Battery Conference) 2025

December 9-11

Caesars Palace

Las Vegas, NV

The use of carbon fiber reinforced thermoplastic (CFRTP) composites, which have higher specific strength than conventional materials and excellent processing and forming properties, is being considered as structural materials in automobiles, where strength and durability are required.

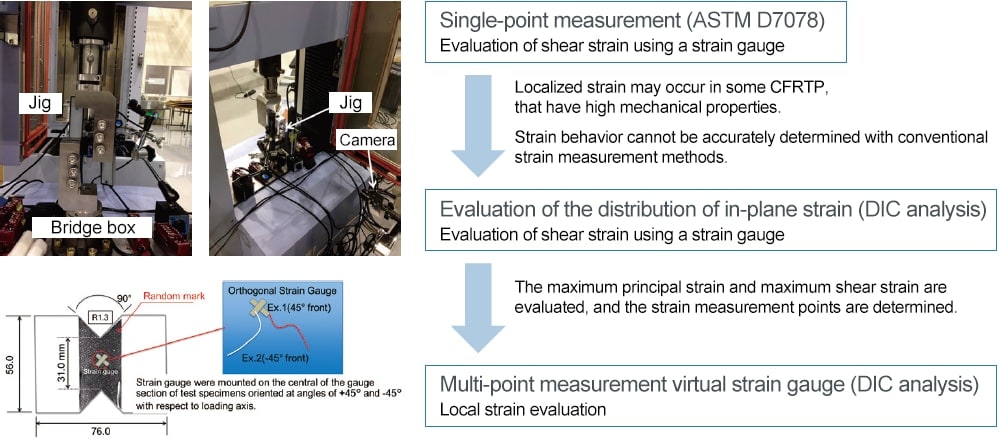

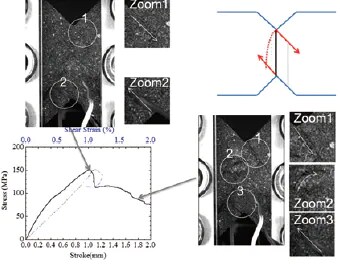

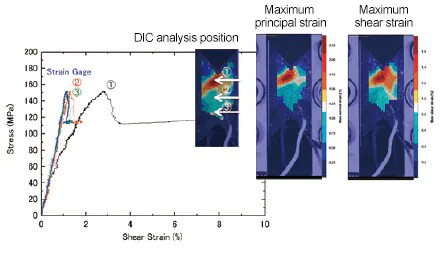

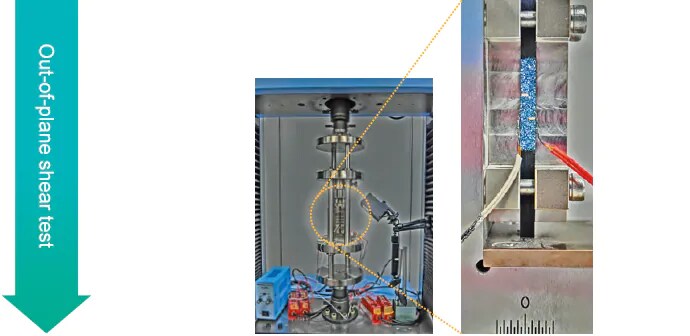

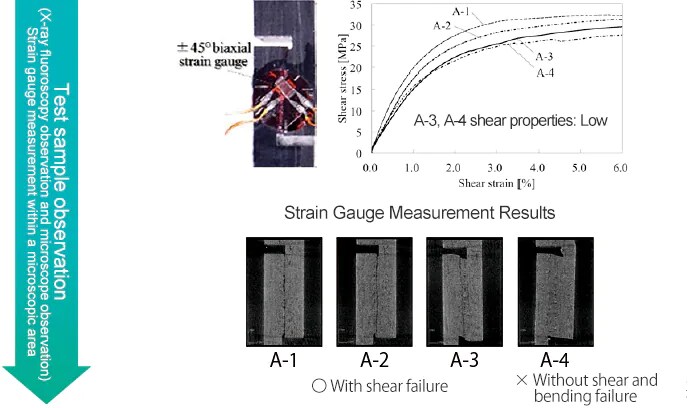

Unlike isotropic conventional materials, composite materials such as CFRTPs are anisotropic and exhibit complex failure behavior in tension, compression, bending, in-plane shear, and out-of-plane shear tests, or a combination of these, depending on the principal axes of stress when loaded. When performing testing and evaluation with a view to designing products using CAE analysis, there is a strong need for testing methods that enable genuine evaluation of these failure behaviors. Here we introduce an example of using a testing system that can evaluate the in-plane and out-of-plane shear properties of composite materials to evaluate one type of CFRTP, namely chopped tape randomly laminated material (CTT, polypropylene base).

Test Sample Shape, Strain Gauge Installation Position, and Random Mark Coated Part

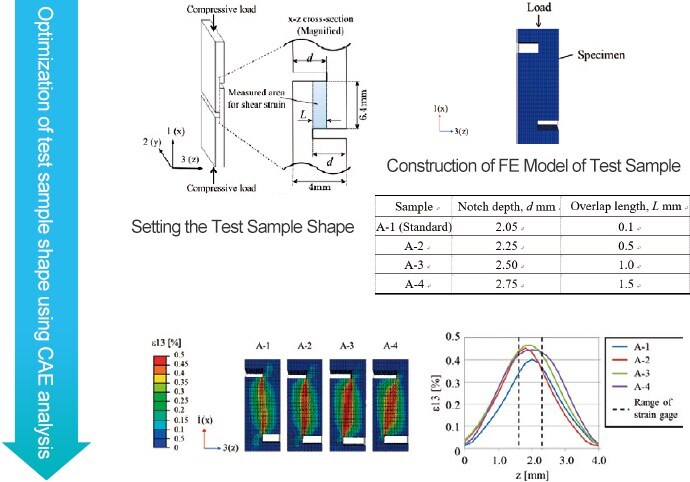

Dependence of Out-Of-Plane Strain Distribution on Test Sample Shape (CAE Analysis)

Test Sample Fixing Jigs and Parallelism Adjustment Plates

Acknowledgments

A part of this research was performed as part of the Japanese Ministry of Economy, Trade and Industry—NEDO sponsored project “Research and Development of Innovative Structural Materials,” and we are grateful to all those that were involved.