AABC (Advanced Automotive Battery Conference) 2025

December 9-11

Caesars Palace

Las Vegas, NV

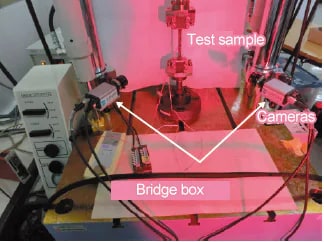

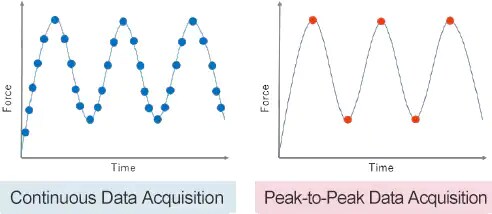

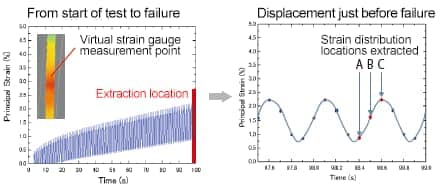

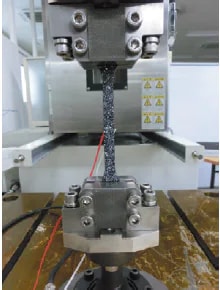

Previously, it was often difficult to predict the appropriate fatigue life during fatigue testing that applied dynamic test forces or strains at high speeds due to stress concentration in the areas measured with conventional strain measurement methods that use contact-type sensors. For this reason, in recent years, analysis by digital image correlation (DIC) has attracted attention as a testing technique that can be used to accurately evaluate the static and dynamic mechanical characteristics of materials in the elastic and plastic ranges. The fatigue characteristics of such materials can now be comprehensively evaluated by installing a three-dimensional DIC analysis system in the fatigue and durability testing machine.

| Instrument Used | EHF-U series hydraulic fatigue and durability testing machine |

|---|---|

| Control Method | Stress control, upper tensile stress 20 MPa and lower tensile stress 2 MPa |

| Test Speed | 2 Hz |

| Strain Measurement | Q400 3-dimensional digital image correlation system 35 mm fixed-focus lens Istra4D control and analysis software for image correlation (Dantec Dynamics K.K.) Frame rate: 10 fps KFG-2-120-D16-11L1M2S strain gauge (Kyowa Electronic Instruments Co., Ltd.) (affixed to back side of sample) DC-97A dynamic strain gauge (Tokyo Measuring Instruments Laboratory Co., Ltd.) |

| Test Sample | JIS K 7161 1A Polypropylene |

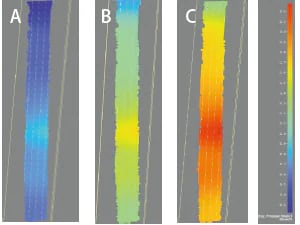

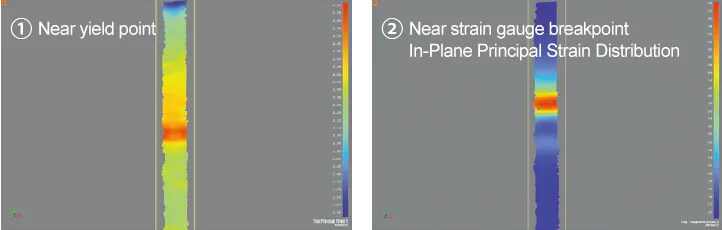

In-Plane Principal Strain Distribution (Confirmation of Strain Concentration Locations)

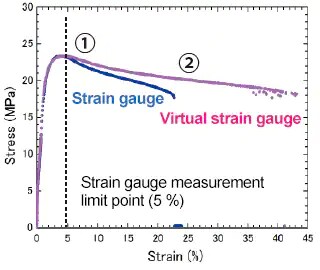

Note: The virtual strain gauge is a function included in the DIC analysis software that can measure displacement at any arbitrarily specified point on the sample observation surface.

In-Plane Principal Strain Distribution

This system can also be used for static tensile testing.