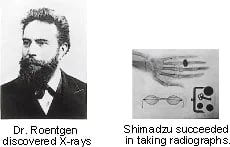

History of Non-Destructive Testing

Shimadzu X-ray technology is a major part of Japan's fluoroscopic technology history

Shimadzu Corporation made history in 1909 by developing Japan's first

commercial application of a medical X-ray apparatus. In fact, one could

say X-ray equipment is one of Shimadzu's core technologies. Shimadzu

has consistently acted as a pioneer in the development of X-ray

technology both in Japan and overseas, leveraging its accumulated X-ray

expertise to become one of Japan’s top manufacturers in not only the

medical field, but in a variety of industrial fields as well.

NDT began in Shimadzu as a part of the “medical division”. The industrial X-ray apparatus “WELTES” was developed by applying X-ray technology cultivated in the medical equipment field, and was first released commercially in 1933. At that time, with improvements in welding technology, a need arose for non-destructive testing of steel pipe welds in factories. Customers were waiting for the release of an industrial X-ray device strong enough to penetrate steel plates. .Thus, “WELTES” was released. Subsequently, an X-ray fluoroscopic system with an image amplifier was released in 1962, and a system for electronic devices was released in 1984. Shimadzu then succeeded in developing Japan’s first microfocus X-ray CT system in 1999, and has since come to be regarded as Japan's top NDT manufacturer.

These days, even though NDT is focused on the standard microscopic inspection, we have also had a number of large-scale, custom order units. In addition to conventional welded steel pipe inspection units, custom-orders included aluminum wheel inspection units, inspection units for large-scale tires of 4 ton, and inspection units at shipyards. With the development of Japan's H1 rocket came a demand for inspections of rocket fuel tanks. In response to this, Shimadzu developed the “Betatron”, an instrument with a maximum output of 25 MeV. After it was delivered and used for testing, during subsequent launches from Tanegashima Island a close watch was kept on the rocket as a kind of prayer for a good outcome. launches were incident-free, thanks to those X-ray inspections.