Nexera Flow Pilot

Mobile Phase Monitor (MPM-40)

Running out of mobile phase is a headache that nearly every analytical chemist has dealt with in the past. In addition to the time spent re-wetting the HPLC there is the risk that buffers will precipitate in the instrument, causing damage to parts and requiring an expensive repair.

Shimadzu’s new Mobile Phase Monitor (MPM) is an accessory offering gravimetric monitoring of the mobile phase remaining on an instrument. The MPM is a vendor neutral solution that can be used on nearly any HPLC system. When the remaining mobile phase reaches a user-specified level, the MPM will automatically stop the batch to ensure the system is not run dry.

The MPM consists of three parts:

- MPM-40 System Controller

- Mobile Phase Balances

- Stand-alone software for MPM control

Figure 1. MPM-40 with bottle holders.

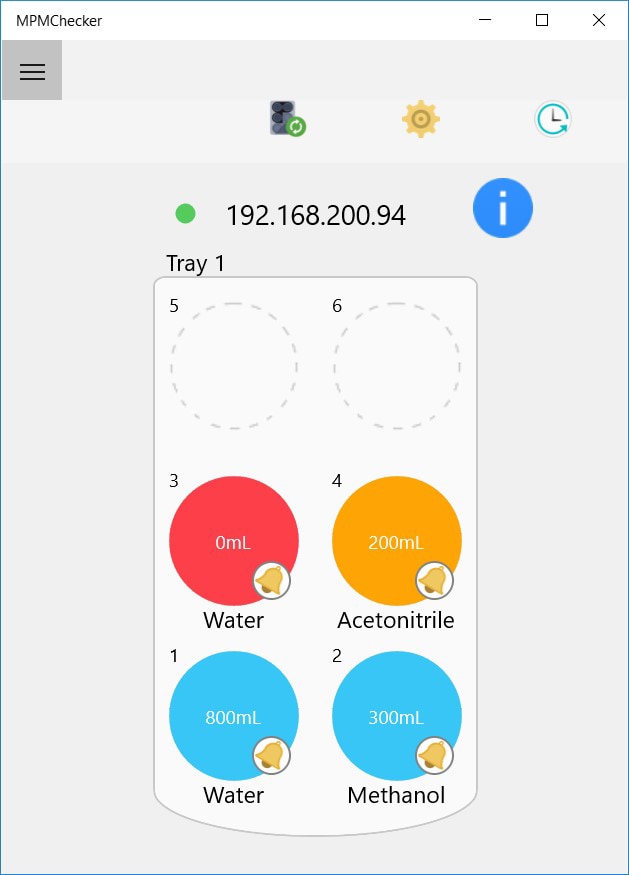

Each Mobile Phase Balance can monitor the level of two 1 L bottles or one bottle up to 5 L in volume. When the MP reaches the user specified Warning Level a notification is sent to the user. When the Error Level is reached the pumps are stopped, preventing damage to the instrument.

The user interface is simple and intuitive to understand at a glance. When the MP bottles are replaced the software will register the change in weight and update the volume automatically.

Figure 2. User interface with both Warning and Error levels displayed.

When used in conjunction with LabSolutions the MPM calculates the exact amount of mobile phase needed to complete the analysis before the batch is started. If there is not enough mobile phase to complete the run the MPM will inform the user. MP can be added to the system after the batch has started to prevent the MPM from stopping the sequence.