Nexera Temperature Controlled Optics

Nexera Intelligent Startup Feature

There is a saying that “Time wasted is money wasted”. This is especially true in a testing laboratory. Time that an analytical instrument is idle represents a reduced testing load, a lower return-on-investment, and a less profitable business.

A laboratory analyst typically spends 1-2 hours preparing an HPLC for a new analysis each day. This process involves purging the instrument to remove air and old mobile phase, warming up the oven and equilibrating the baseline, and performing “test” injections of a known compound to determine if the instrument is performing appropriately. These steps are critical but represent time that the instrument and analyst are not generating test results and sample data.

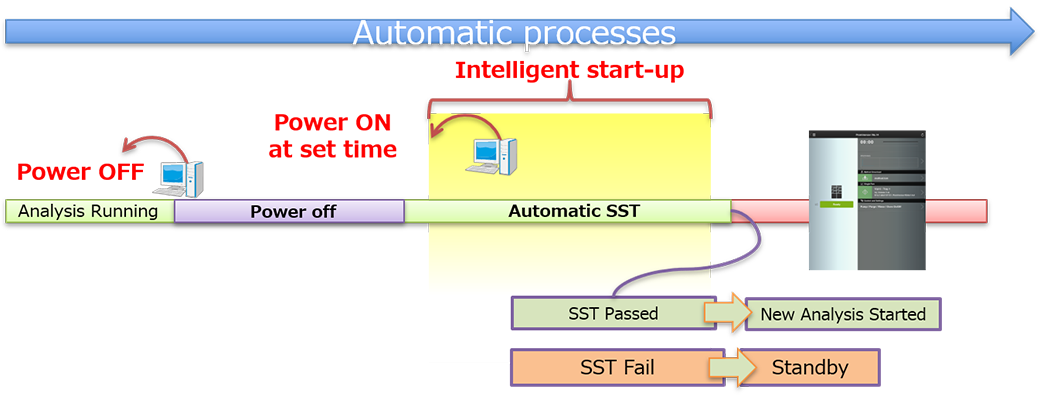

Shimadzu’s Nexera LC-40 addresses this productivity issue by incorporating an Intelligent Startup feature to prepare the instrument for use before the analyst arrives in the lab. Based on user-programable methods, the instrument will perform a purge and equilibration at a specified startup time, followed by an injection of a known compound to evaluate instrument performance.

After performing the test injection, the instrument evaluates the results against preset criteria to determine system suitability. If the system suitability fails, the instrument will report the failure and enter a standby mode. This allows the analyst to evaluate the results when they arrive and take corrective action. If the injection passes system suitability the instrument can go on to inject further standards and samples without intervention of the analyst, saving time and increasing the productivity of the lab.

Contact Shimadzu to find out more about the new Intelligent Startup feature of the Nexera LC-40!