Electromagnetic Type and Load Cell Type

Various principles are used for measuring the weight of objects. The following briefly describes the operating principles and features of the two most popular methods, "electromagnetic type" and "load cell type."

● Electromagnetic Type

This is also called the "electromagnetic balance method." With mechanical balances, the sample is placed at one end of the beam and the weight is placed at the other end, and the value of the weight when both are perfectly balanced becomes the mass of the sample. With electromagnetic type balances, an electrical force (electromagnetic force) is applied instead of a placed weight to balance the beam. The amount of electricity required for balancing the beam changes according to the weight of the sample that is placed. The amount of current when the beam is perfectly balanced is detected, and the mass is obtained from that detected value.

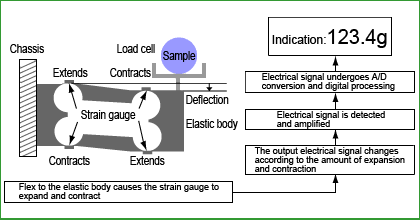

● Load Cell Type (electrical resistance wire method)

One end of an object (elastic body) made of aluminum and shaped as shown in the figure is fixed in place, and the sample is placed on the other end. The weight of the sample causes the elastic body to flex. The amount of flex causes the strain gauges attached to the elastic body to expand and contract, changing the amount of electricity that is output (strictly speaking, the resistance value). The mass is then obtained from that amount of electricity.

● Comparison Between Electromagnetic Type and Load Cell Type

|

Electromagnetic Type

|

Load Cell Type

|

|

| Advantages |

|

|

| Disadvantages |

|

|

| Applications |

|

|

| Name of Series |

|

|