Measurement Methods for Rubber Samples

■ Introduction

What we call rubber contains many types of components. Some products contain a single component, while others contain a mixture of two or more components. Vulcanized rubber also contains non-rubber components, such as vulcanization accelerators, antioxidants, and fillers. Obtaining an infrared spectrum for rubber requires pretreatment that is appropriate for the sample shape and the type and quantity of coexisting substances. The typical measurement methods for rubber samples introduced below include the thin-section method, solubilization method, thermal decomposition method, ATR method, and pyrolysis-GC-FTIR method.

■ Thin-Section Method

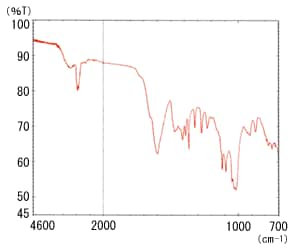

Fig. 1 Transmission Spectrum of Blended Rubber (Butyl - Natural Rubber) by Thin-Section Method (after Baseline Correction)

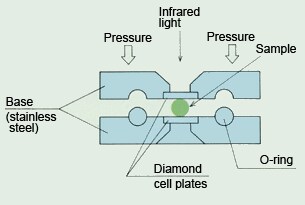

This is a method of cutting thin sections from a rubber sample and conducting analysis by the transmission method. It permits analysis of rubber samples without pretreatment such as extraction or dissolution. A microtome is used to slice the samples. As rubber is soft, it must be frozen before slicing. Therefore, a microtome with a chiller is required. A method using a diamond cell is another way to obtain thin rubber sections. A small rubber fragment is compressed between two diamond aperture plates to create a thin film of rubber. This pretreatment is comparatively simple, and does not demand the high degree of skill required to use a microtome. Fig. 1 shows transmission measurements by infrared microscope on a thin section of a blend of butyl rubber and natural rubber in a diamond cell.

Fig. 2 Structure of a Diamond Cell (Type B)

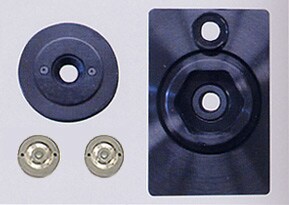

Fig. 3 Appearance of a Diamond Cell

■ Thermal Decomposition Method

The sample is thermally decomposed and the distillate is measured by the transmission method. The sample is placed in a test tube and the base of the test tube is heated using a Bunsen burner. Condensate that forms in the cool portion at the top of the test tube is directly applied to NaCl or KBr aperture plates and the infrared spectrum is measured. As the spectrum also incorporates compounding ingredients, it often differs from the spectrum of crude rubber.

■ Solubilization Method

The sample is extracted in an acetone/chloroform (32:68) mixed solution and components such as free sulfur, wax, mineral oil, and softening agent, are eliminated. Next, a high-boiling-point solvent, such as o-dichlorobenzene or tetrachloroethane is added and recirculated for 2 to 30 hours until the contents are fully dissolved. After cooling, toluene is added and the insoluble matter is filtered out. The liquid obtained is vacuum-concentrated and applied to a KBr aperture plate. The solvent is allowed to dry and the infrared spectrum is measured using the liquid membrane technique. This method involves time-consuming dissolution of the sample, but can generate a spectrum similar to that of crude rubber.

■ Attenuated Total Reflection (ATR) Method

Fig. 4 ATR Spectrum of Blended Rubber (Butyl - Natural Rubber)

The ATR method is an extremely simple measurement technique that requires no sample pretreatment, unlike the methods described above. The sample is pressed against a high-refractive-index prism, such as KRS-5 or Ge, and the infrared spectrum of the sample surface is measured. Ideally the sample should be in sheet form. However, samples of any shape can be measured as long as they can be pressed against the prism. A high-refractive-index germanium (Ge) prism is required to analyze black rubber that is high in carbon black content. As the ATR method obtains information on the material up to a depth of several µm from the sample surface, care is required in spectrum analysis if the sample composition varies depending on the depth direction or if the sample contains surface deposits. Fig. 4 shows the ATR spectrum of the same sample as Fig. 1.

■ Pyrolysis-GC-FTIR Method

The thermal decomposition method described above allows for analysis only of the condensed components from thermal decomposition. Conversely, pyrolysis-GC-FTIR permits online infrared spectrum measurements for the separated components after the thermal decomposition products are introduced directly into a gas chromatograph (GC). The sample is first thermally decomposed by heating in a thermal decomposition device. After separation in the GC column, some components are sent to the FID detector and the remainder to an FTIR cell called a "light pipe cell." A heating furnace or a high-frequency induction heating furnace (Curie point type) is often used as the thermal decomposition device.

As pyrolysis-GC-FTIR can measure the infrared spectrum for each separated component, it permits the qualitative analysis of the various components added as compounding ingredients, in addition to the rubber components. As GC-FTIR becomes commonplace along with technical advances in FTIR, this method is likely experience widespread use in the analysis of rubber.

■ Conclusions

The measurement methods for rubber samples are outlined above. A comparison of Fig. 1 and Fig. 4 shows that the spectrum differs depending on the pretreatment method used. Therefore, rubber must be identified by comparing the infrared spectrum to standard spectra obtained using the same method of pretreatment.

■ Reference

Japan Society for Analytical Chemistry, Division of Polymer Analysis and Characterization, "Koubunshi Bunseki Handobukku (Polymer Analysis Handbook), p. 516-520, Asakura Publishing Co., Ltd. (1986)