Chapter 4: What is a TG-DTA?

Simultaneous Thermogravimetry and Differential Thermal Analysis

This analyzer can simultaneously perform differential thermal analysis and thermogravimetric analysis with a single sample.

Melting, Glass Transitions, Crystallization, Curing Reaction, Sublimation, Evaporation, Dehydration, Pyrolysis, Examination of Thermal History

TG and DTA Curve Models and Thermal Changes in the Air

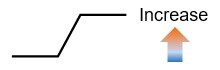

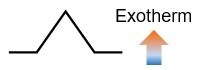

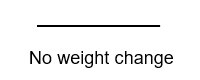

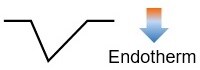

| TG Curves | DTA Curves | Reactions |

|---|---|---|

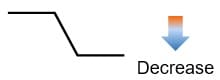

|

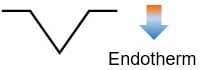

|

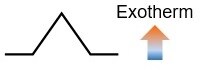

|

Decomposition, Dehydration, Reduction |

|

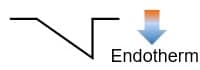

|

Combustion | |

|

|

Sublimation, Evaporation | |

|

|

|

Oxidation |

|

|

|

Transition, Melting |

|

|

Crystallization | |

|

|

Glass transition |

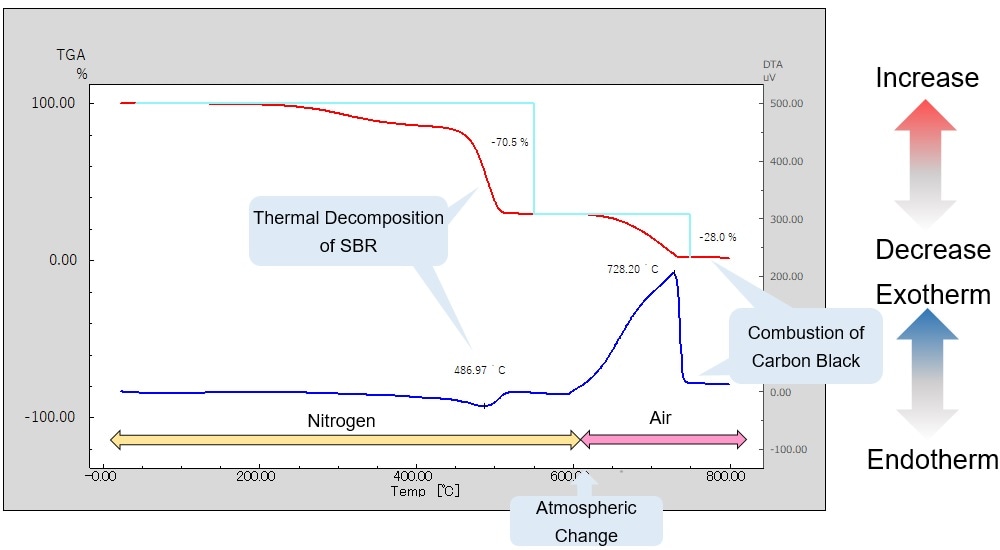

Sample Data of a TG-DTA

Styrene-butadiene rubber (SBR) contains carbon black in order to improve its mechanical strength and thermal resistance. Heating while controlling the atmosphere enables quantifying the added carbon black.

First, set a sample in the analyzer, and then change the atmosphere sufficiently to nitrogen. By heating the sample to approximately 600℃, endotherm with weight reduction can be seen. This indicates that the SBR is pyrolyzed. When changing the atmosphere to air after the SBR is completely decomposed, exotherm with weight reduction is observed. This suggests that the carbon black is oxidized. Therefore, 28%, which is the second reduction, proves to be the amount of the carbon black added to the SBR. Additionally, inorganic residues are generated after the carbon black is oxidized.

Thus, simultaneous measurement of weight changes and calories with a TG-DTA enables determining what kind of reaction it is with more accuracy.