ASTM C39: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens

ASTM C39 is a standard used to measure the compressive strength of cylindrical concrete specimens, such as molded cylinders or drilled cores. This test is essential for determining the ability of concrete to withstand loads that compress it, making it critical for structural design and quality control in construction. Results from ASTM C39 help engineers and contractors ensure that concrete used in buildings, bridges, and other structures meets strength requirements.

This webpage provides an overview of ASTM C39, but it is recommended that users refer to the full ASTM C39 standard for complete details on procedures and requirements.

ASTM C39 Properties of Interest

The key mechanical and material properties specified in ASTM C39 include:

Compressive Strength: The maximum stress the concrete specimen can withstand before failure under a compressive load.

Modulus of Elasticity: How the concrete deforms elastically under load before failure.

Failure Mode: The classification of how the concrete fails, which provides insight into material characteristics. Some examples are diagonal fracture, side fracture, well-formed cones, etc..

ASTM C39 Testing Setup and Method

Testing for ASTM C39 is conducted using a universal testing machine (UTM) with compression fixtures and accessories for cylindrical concrete specimens. The typical setup includes:

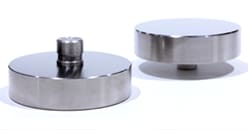

Compression Platens: Steel plates that apply the load evenly across the top and bottom of the specimen.

Load Cell: Provide precise measurement of the tensile force applied to the specimen.

Extensometers (Optional): Used to measure strain and elasticity, depending on the setup.

ASTM C39 Software Features

-

The software used for ASTM C39 testing plays a critical role in data acquisition, analysis, and reporting. TrapeziumX-V Key features include:

Real-time Load and Stress Monitoring: Software records load, displacement, and stress in real time during the test.

Automated Reporting: Generates standardized test reports, including load, displacement, and stress-strain curves.

-

ASTM C39 Specimen Details

Size: Cylindrical specimens, typically 6 inches in diameter by 12 inches in height, though 4x8-inch cylinders are also used.

Curing: Specimens are cured under controlled conditions for 28 days before testing to ensure accurate strength measurement.

Surface Prep: Flat, smooth ends are required to ensure even load distribution during testing.