ASTM E8: Standard Test Methods for Tension Testing of Metallic Materials

ASTM E8 is a widely used standard that specifies the methods for determining the tensile properties of metallic materials. This test measures the strength and ductility of metals under uniaxial tensile stress, providing essential data for quality control, material selection, and design in industries such as aerospace, automotive, and construction. By testing to failure, ASTM E8 reveals the tensile strength, yield strength, and elongation of metal specimens, helping engineers and manufacturers ensure that metals meet the required performance standards for specific applications.

This webpage provides an overview of ASTM E8, but it is recommended that users refer to the full ASTM E8 standard for complete details on procedures and requirements.

ASTM E8 Properties of Interest

The primary properties measured by ASTM E8 include:

Ultimate Tensile Strength (UTS): The maximum stress that a material can withstand while being stretched or pulled before breaking.

Yield Strength: The stress at which a material begins to deform plastically and experiences permanent deformation.

Elongation: The amount of stretch a material undergoes before breaking, expressed as a percentage of the original gauge length.

Reduction of Area: A measure of ductility that calculates the change in cross-sectional area after fracture.

Modulus of Elasticity (Optional): The stiffness of the material, calculated from the slope of the stress-strain curve in the elastic region.

ASTM E8 Testing Setup and Method

Testing for ASTM E8 is performed using a universal testing machine (UTM) with specialized grips and accessories for metallic specimens. The typical setup includes:

Hydraulic or Mechanical Grips: These grips securely hold the specimen in place during the test, ensuring no slippage occurs as tensile forces are applied.

Load Cells: Provide precise measurement of the tensile force applied to the specimen.

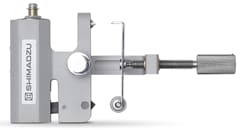

Extensometers: Used to measure the elongation or strain of the specimen with high precision, especially within the gauge section.

Furnaces or Environmental Chambers: Sometimes used to test the tensile properties of metals at elevated temperatures or under specific environmental conditions, depending on the material application.

ASTM E8 Software Features

-

TRAPEZIUMX-V used for ASTM E8 testing is critical for capturing data accurately and efficiently. Key features include:

Real-time Stress-Strain Curve Plotting: Displays the behavior of the metal under load, allowing operators to visualize key points like yield and ultimate tensile strength.

Automatic Calculation of Key Parameters: The software calculates tensile strength, yield strength, elongation, and reduction of area automatically, reducing the likelihood of errors.

Statistical Analysis and Reporting: The software can generate reports that include statistical analysis of test results for quality control and compliance.

-

ASTM E8 Specimen Details

ASTM E8 specifies the size and shape of metallic specimens to ensure consistent and comparable test results. Specimen details include:

Standard Specimen Types: Specimens are typically prepared in one of two shapes: rectangular or cylindrical. Cylindrical specimens are more common for metals.

Gauge Length and Diameter: The gauge length is the central portion of the specimen where deformation is measured. Typical cylindrical specimens have a gauge length of 2 inches with diameters of 0.505 inches (for standard tests).

Surface Preparation: Specimens must have a smooth surface, with no imperfections, to ensure accurate stress and strain measurements. The ends must be parallel and free of burrs to fit securely into the grips.

Testing at Elevated Temperatures (Optional): For certain applications, specimens may be tested at elevated temperatures using furnaces to simulate real-world operating conditions.