AABC (Advanced Automotive Battery Conference) 2025

December 9-11

Caesars Palace

Las Vegas, NV

In recent years, GFRPs (Glass Fiber Reinforced Plastics), which have high specific strength, excellent workability and moldability, have been widely applied to electronic substrates, ships, automobile exteriors, etc., and have become indispensable materials. Composite materials, such as GFRPs, are anisotropic and have a complicated internal structure, so they exhibit complex deformation/fracture behavior related to tension, compression, bending, in-plane shear, out-of-plane shear, or a combination of these. In order to design an accurate product, there is a strong demand for a test method that can evaluate each fracture behavior individually. In particular, it is said that out-of-plane shear characteristics are difficult to obtain. In this case, the applicability of a test method was verified by conducting a new out-of-plane shear test, which improves upon JIS K7092, for a plain weave GFRP, which is a widely used composite material, and comparing it with the analysis results.

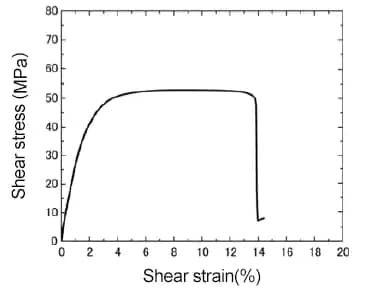

Result of out-of-plane shear test

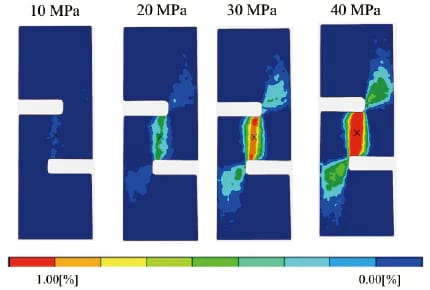

Strain distribution (DIC) during out-of-plane shear test

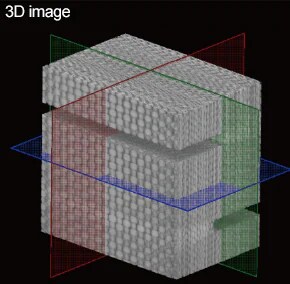

Internal structural data of out-of-plane share test specimen

Simpleware

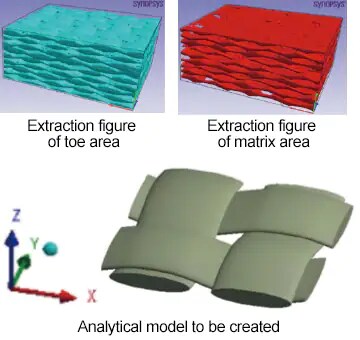

Automatic optimization of tow volume content

Ansys® Workbench

DesignXplorer

Creating an analytical model

Multiscale.Sim

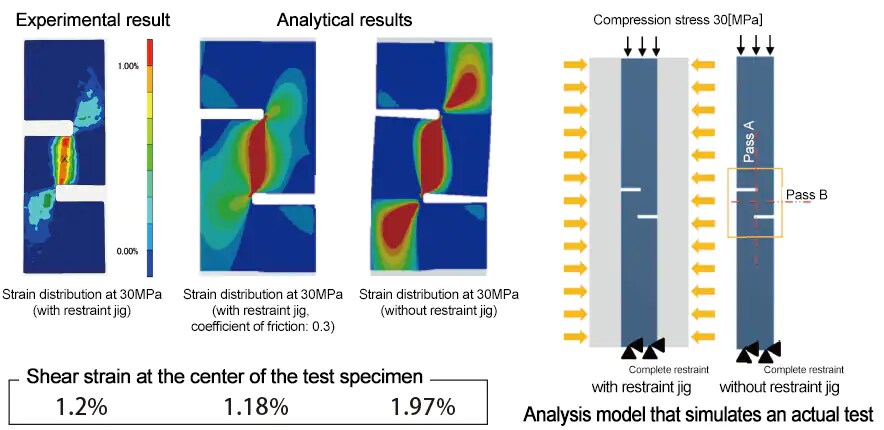

By applying the analysis model using the internal structure data acquired by X-ray CT, analysis results similar to the actual test were obtained.

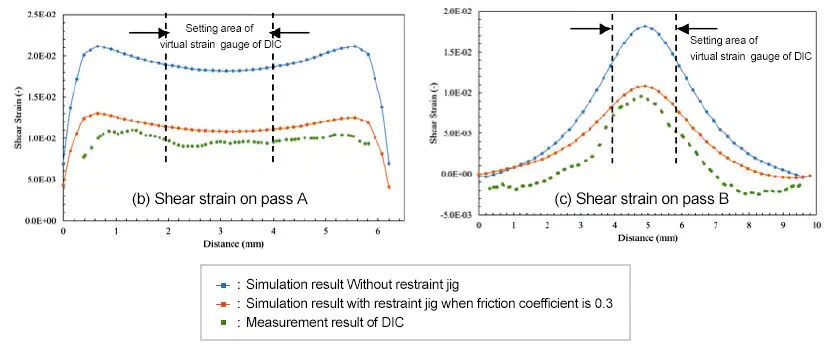

Since the uniformity of the shear strain distribution in the center of the test specimen was maintained in both the actual test and the analysis, this out-of-plane shear test method is one in which shear strain is accurately applied.

The data posted is the result of joint efforts by Shimadzu Corporation and Cybernet Systems Co., Ltd.

Shimadzu Corporation acquired mechanical characteristics and internal structure data, and Cybernet Systems Co., Ltd. conducted CAE analysis.