AABC (Advanced Automotive Battery Conference) 2025

December 9-11

Caesars Palace

Las Vegas, NV

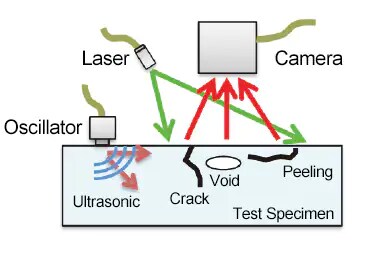

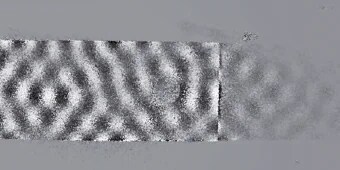

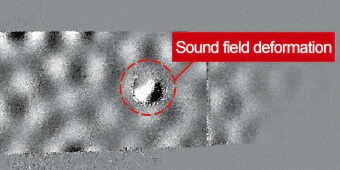

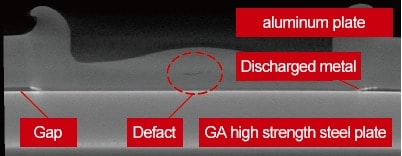

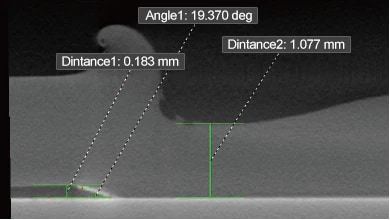

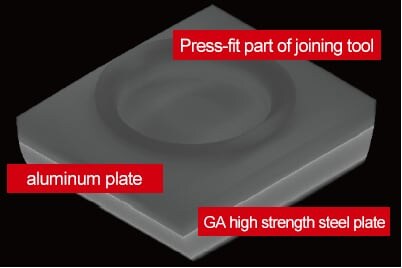

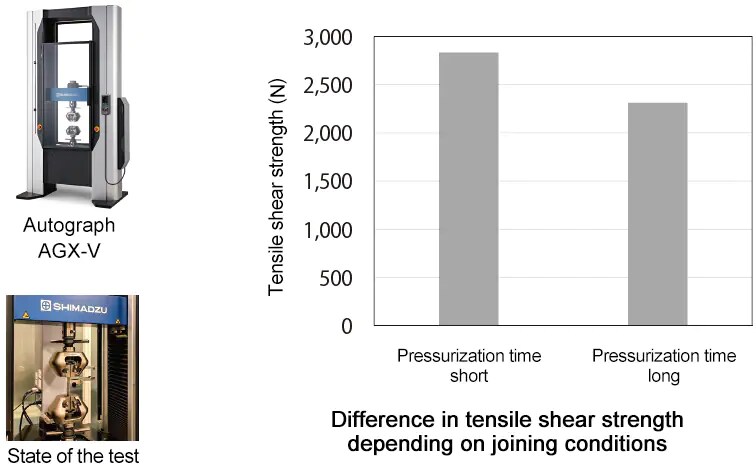

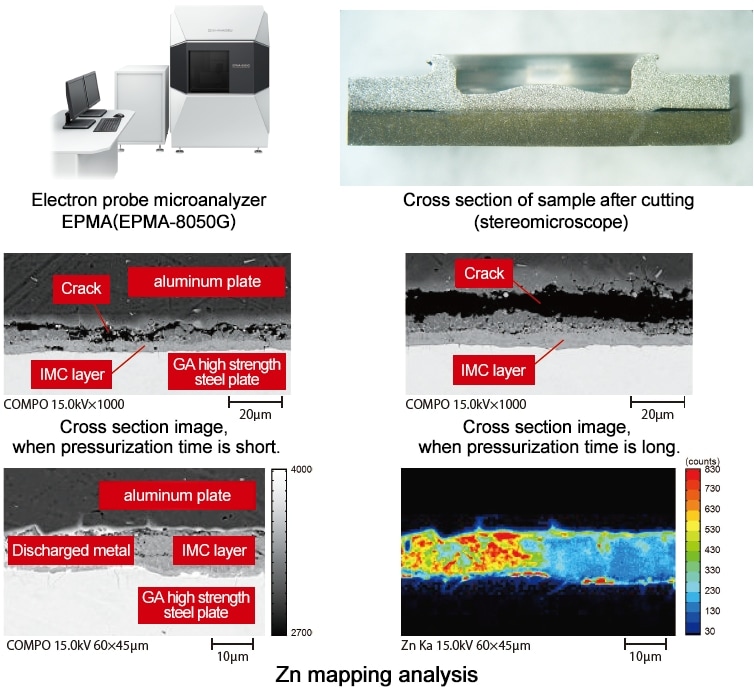

In recent years, reducing the weight of transportation equipment has become an important goal in efforts to reduce greenhouse gas emissions and more effectively use resources. Lightweight and tough materials are generally expensive, so to achieve high-quality, low-cost equipment, it is important to use multiple materials with different characteristics in the right places. In order to promote the use of multiple materials, in addition to the development of bonding technologies for dissimilar materials, it is essential to consider inspection and evaluation methods for bonding materials. In this example, friction stir point welding of dissimilar metals was evaluated in various ways using multiple observation and testing equipment.