AABC (Advanced Automotive Battery Conference) 2025

December 9-11

Caesars Palace

Las Vegas, NV

Carbon fibers are essential components of carbon fiber reinforced plastics (CFRPs). They are important industrial materials because their specific gravity is 1/4 and material strength is seven times higher as compared to general ferrous materials. This experiment introduces a tensile test on a single filament of carbon fiber in accordance with the standards

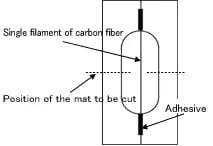

In this test, the sample is fixed on a specimen mat made of a metal or resin sheet and attached on the grip as shown in Fig. 1 and then a tensile test is performed. The standards provide a detailed explanation about the shape of the mat, type of adhesive used to place a carbon fiber on the mat, and procedures to place the carbon fiber. (For details, refer to the standards.)

In the test, a clip type grip is used to adjust the clamping force according to the strength of the sample.

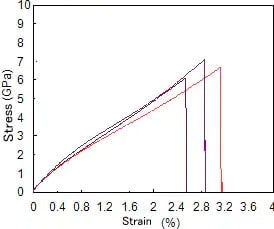

Measurement Results

Fig. 2

Table 1 - Test Conditions

| Item | Setting Value |

|---|---|

| Test Speed | 1mm/min |

| Grip spac | 25mm |

Table 2 - Test Results (Mean Value)

| Sample Name | Diameter | Tensile Strength | Breaking Elongation |

|---|---|---|---|

| Carbon Fiber | 6μm | 7.1GPa | 2.84% |

| Testing machine | MST-I Type HR |

|---|---|

| Title | 1 N clip type grip (with rubber-coated grip faces), X-Y stage |

| Title | TRAPEZIUM X (Single) |

Features