AGX-V2 Series AUTOGRAPH Precision Universal Tester

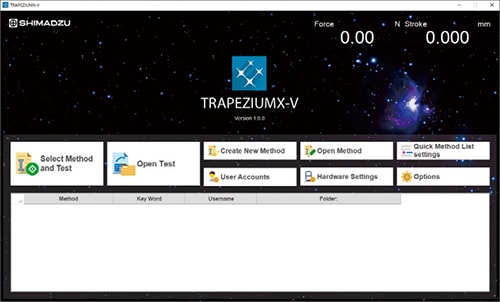

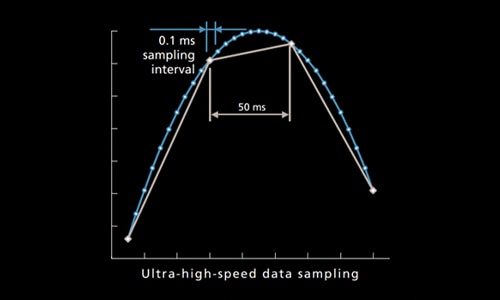

At Shimadzu, our aim is to develop instruments that provide the highest level of test results. To this end, we created the AGX-V2, the highest class of testing machine in the industry. It features a high rigidity frame; multi processors, high-speed sampling and high-accuracy automatic control; an intelligent crosshead; stroke limit switches; a high degree of safety; a smart controller equipped with a progressive user interface; and software that supports the creation of test conditions and data processing with intuitive operability.