Enhance Material Testing Efficiency with USF-2000A: Explore Now! - Applications

Ultrasonic Fatigue Testing System

Most of the documents on the LITERATURE is available in PDF format. You will need Adobe Acrobat Reader to open and read PDF documents. If you do not already have Acrobat Reader, you can download it free at the Adobe's Website. Click the GET ADOBE READER icon on the left to download a free copy of Adobe Acrobat Reader.

For Evaluating Fatigue Strength at Cycle Level of 108 or Higher

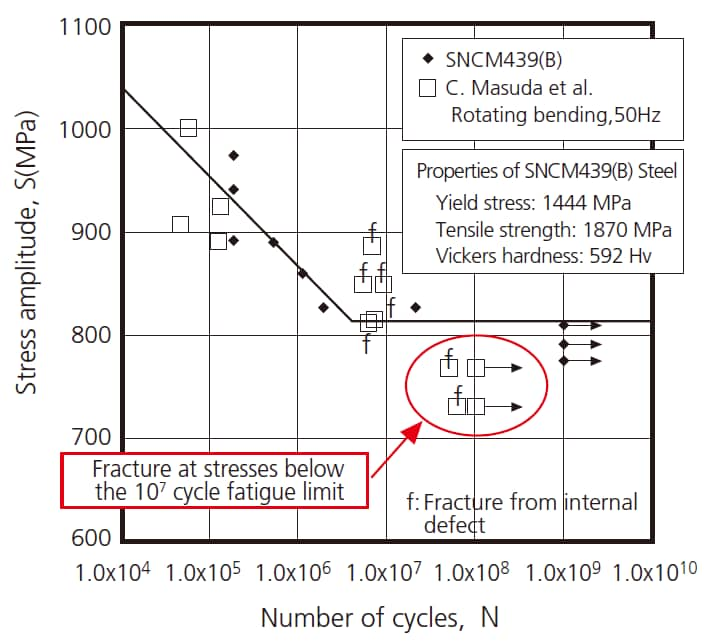

Fatigue Strength of SNCM439(B) Steel

Conventionally, it was assumed that fatigue strength of steel was constant beyond 107 cycles. In other words, it was assumed that fatigue failure would not occur at stresses below the fatigue limit for 107 cycles. However, we are now learning that in the case of materials strengthened by quenching or surface treatment, internal inclusions can cause fatigue fractures between 108 and 109 cycles even for stress levels below the 107 fatigue limit.

Therefore, now that products are being used for longer periods at higher speeds, fatigue fractures between 108 and 109 cycles have become an extremely important issue.

Allows tests of 1010 cycles to be completed in only six days,

which would normally take 3.2 years at 100 Hz.

For Analyzing Inclusions in Test Materials

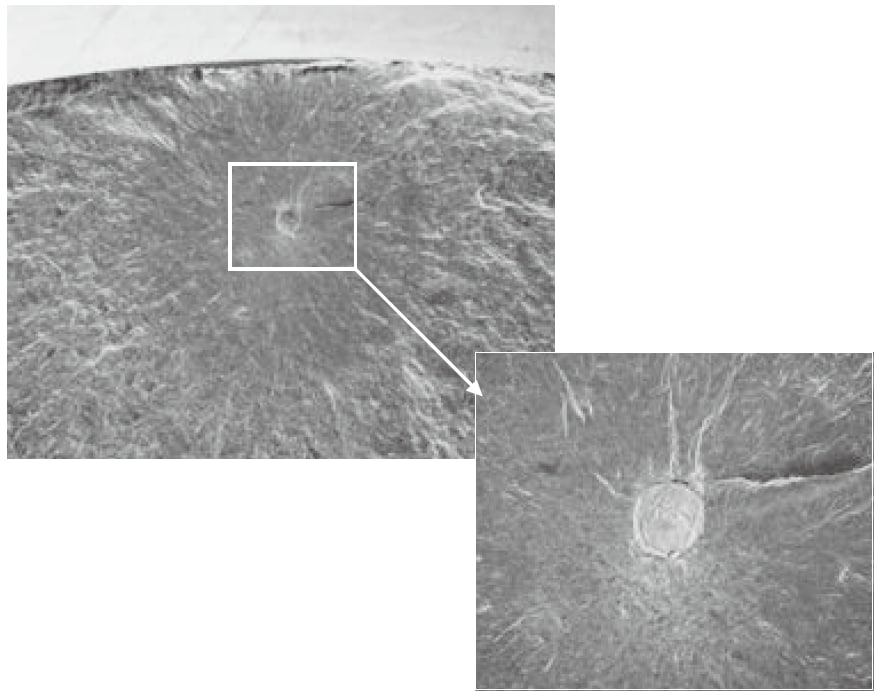

Example of the fatigue fracture surface of high-strength steel fractured by the Shimadzu USF-2000A Ultrasonic Fatigue Testing System

Inclusion where the fatigue fracture originated can be identified

In high-strength steels and other materials, fatigue can propagate from micro defects and inclusions inside the material, which are known to result in fatigue fractures at the gigacycle level. Therefore, identifying and analyzing defects and inclusions in test materials are useful for developing materials with high fatigue strength.

Due to the extremely small size of such defects and inclusions, they are very difficult to identify using non-destructive methods. Typically, materials were sliced and the section surface visually inspected.

However, the efficiency of identifying and analyzing inclusions can be increased dramatically by using an ultrasonic fatigue testing machine to the point of fatigue fracture, which ensures a defect or inclusion will be discovered on the fracture surface.

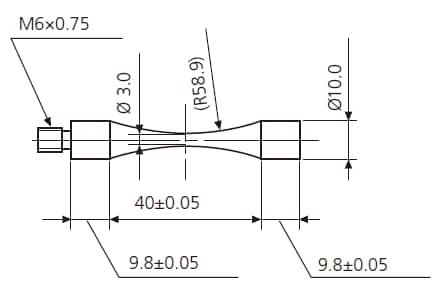

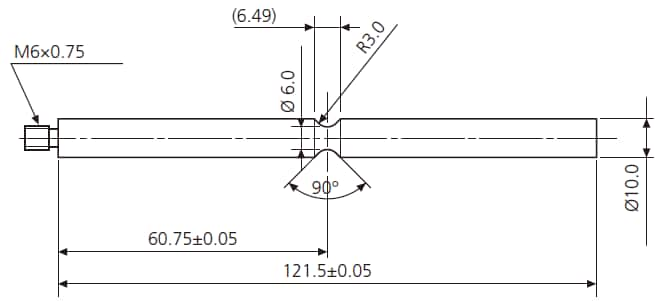

Example of Sample Dimensions (given Young's modulus of 206,000 MPa and density of 7.85 g/cm3)

![]()

Test stress range: About 200 to 1000 MPa nominal

![]()

Test stress range: About 140 to 700 MPa nominal

Stress concentration factor: About 1.56

Units: mm