AGX-V2 Series Precision Universal Tester - Applications

AUTOGRAPH Precision Universal Tester

Steel and Nonferrous Metal Testing

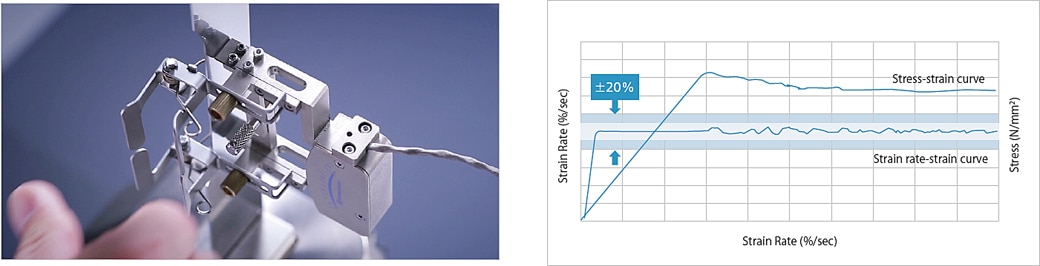

Strain rate control, in which the rate of deformation measured by an extensometer is controlled to be constant, requires highly accurate control to follow rapid changes in material behavior.

Metal Tensile Test Standard: ISO 6892:2016(JIS Z 2241:2011) specifies that the allowable range of increase in strain to the yield point is ± 20% or less. The strain rate control specified in ISO 6892:2016(JIS Z 2241:2011) is possible*1 to achieve with the AGX-V for many materials.

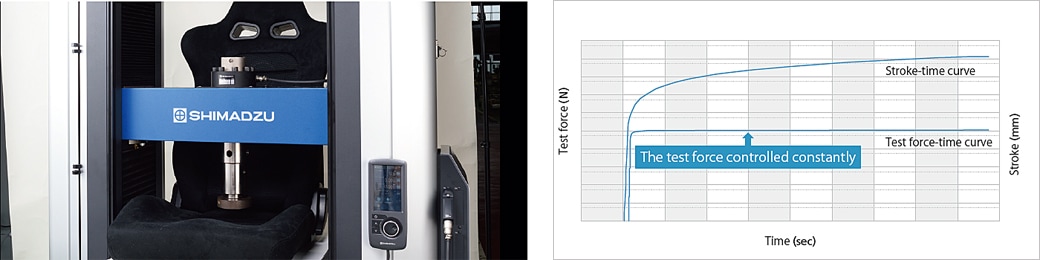

Practical Simulation Testing

To maintain engine mounts and other rubber materials at a constant test force, it is necessary to gradually change the retention position to suit the characteristics of the test sample. To maintain the test force at a constant value requires high control stability, with high control responsiveness and no vibrations generated due to excessive response.

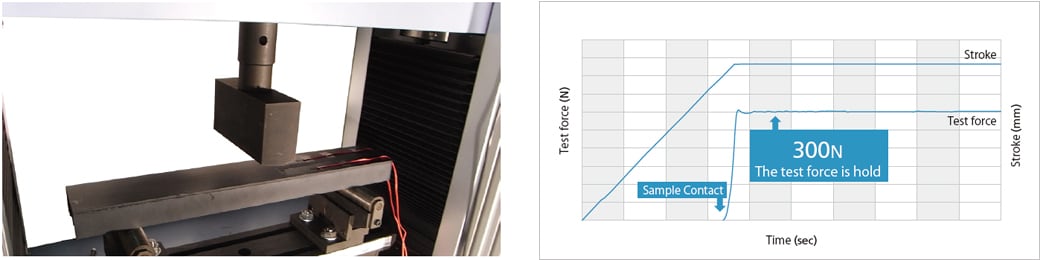

Free Running Compression Testing

Stable control is achieved even in free running compression tests. In these tests, the compression indenter or bending punch is allowed to run free until it contacts the sample, at which point the load is increased up to a set test force. The overshoot of the target value is reduced, even with highly rigid materials, resulting in high-accuracy test force retention.