inspeXio™ 7000 - Applications

Microfocus X-Ray CT System

Most of the documents on the LITERATURE is available in PDF format. You will need Adobe Acrobat Reader to open and read PDF documents. If you do not already have Acrobat Reader, you can download it free at the Adobe's Website. Click the GET ADOBE READER icon on the left to download a free copy of Adobe Acrobat Reader.

-

Aluminum Die Castings

-

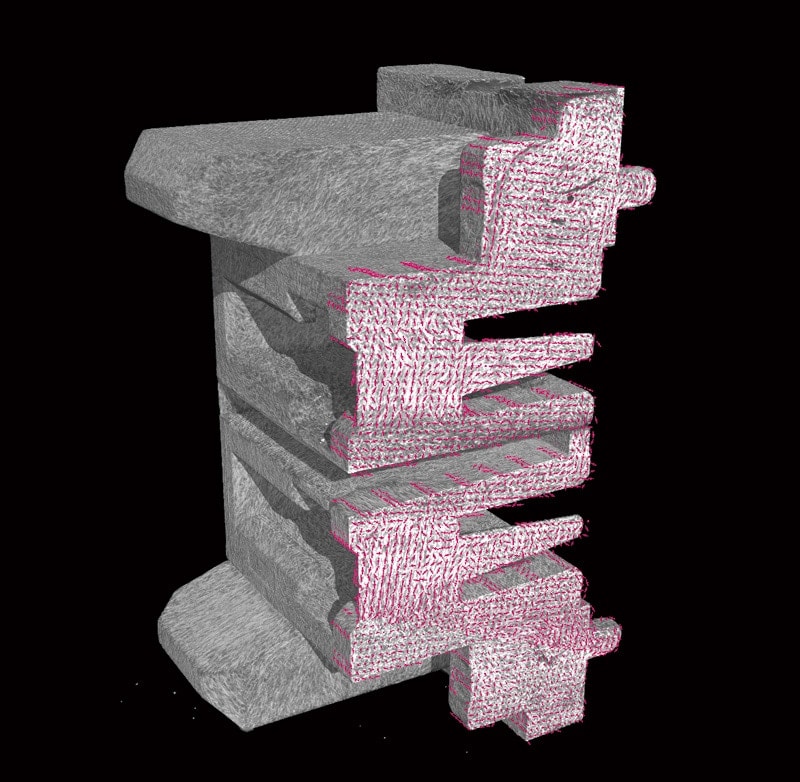

GFRP (Glass Fiber Reinforced Plastic)

-

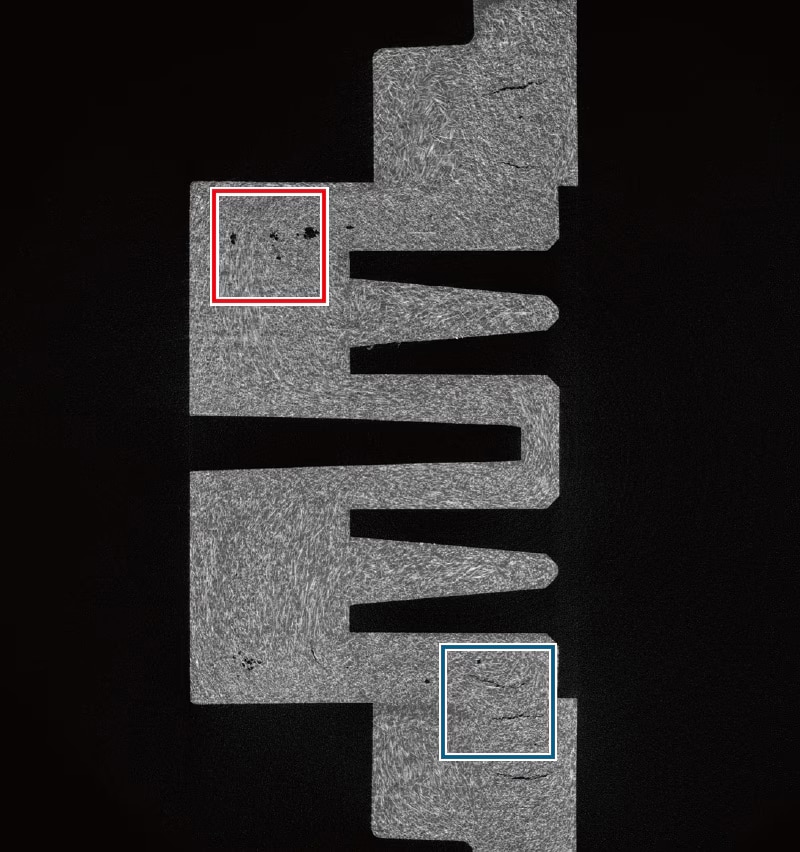

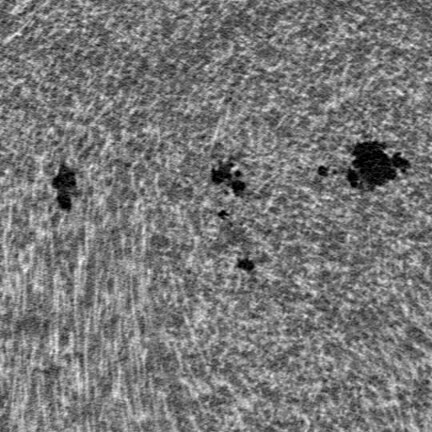

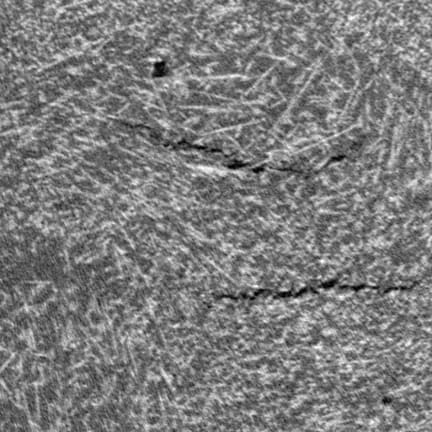

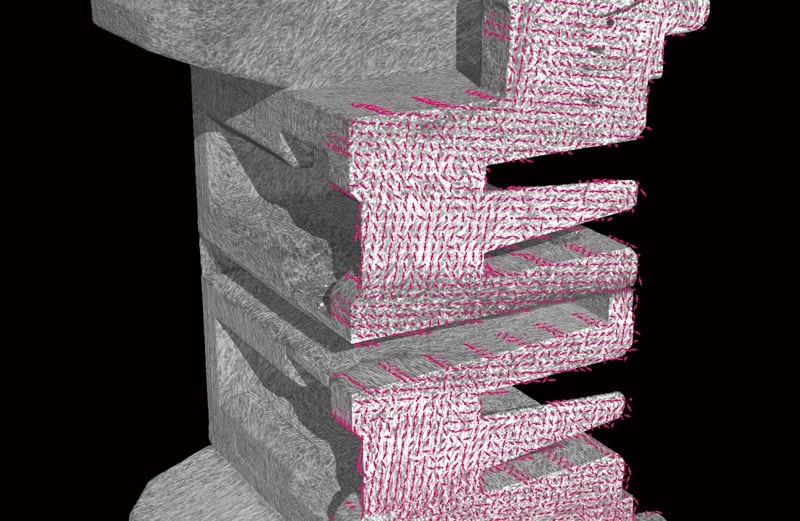

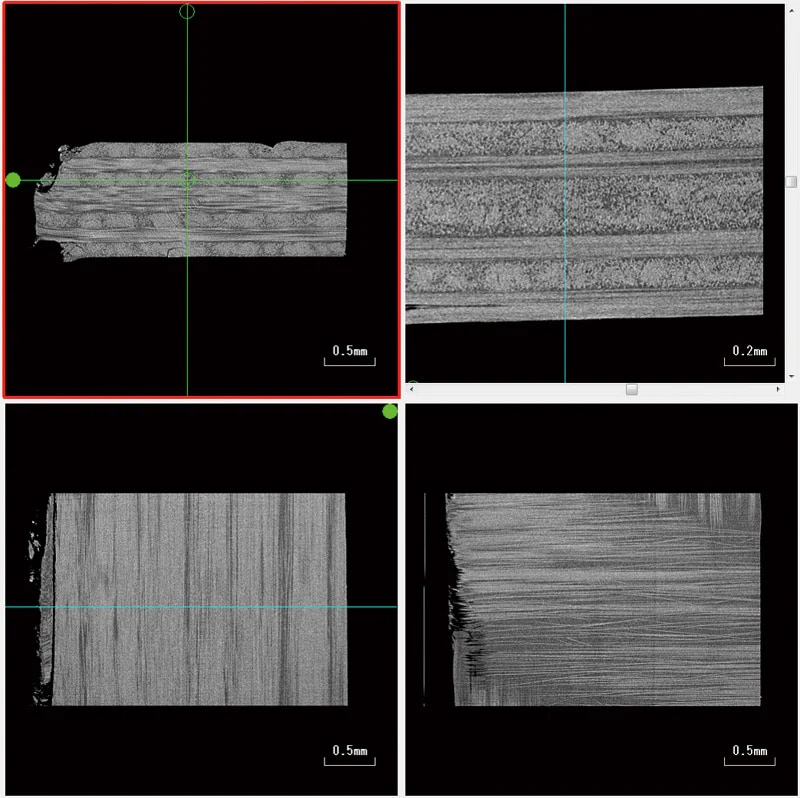

CFRTP (Continuous Fiber Reinforced Thermoplastic Laminate)

-

BGA (Ball Grid Array)

-

Concrete

-

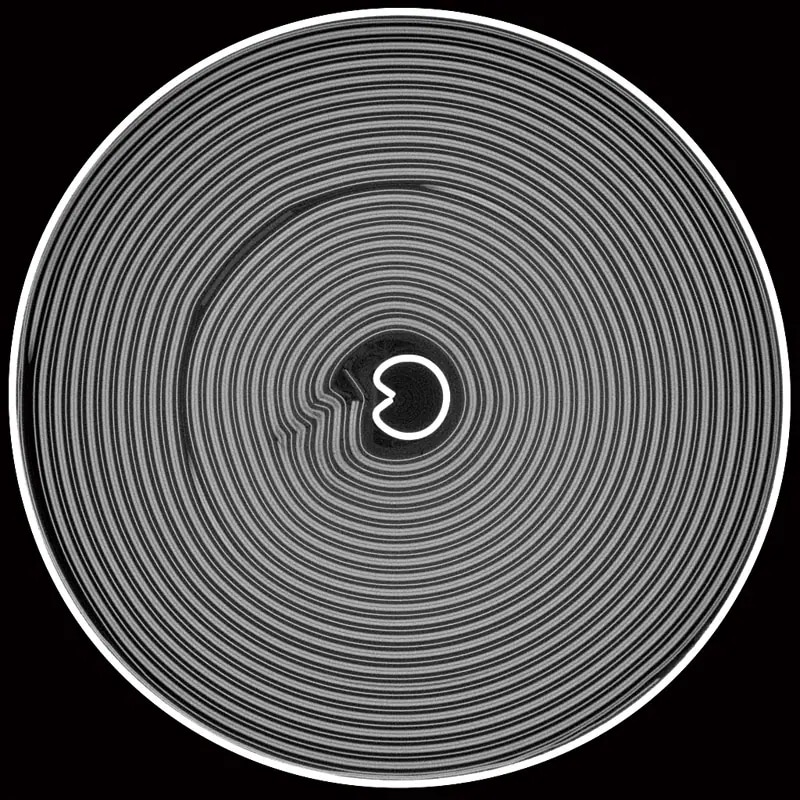

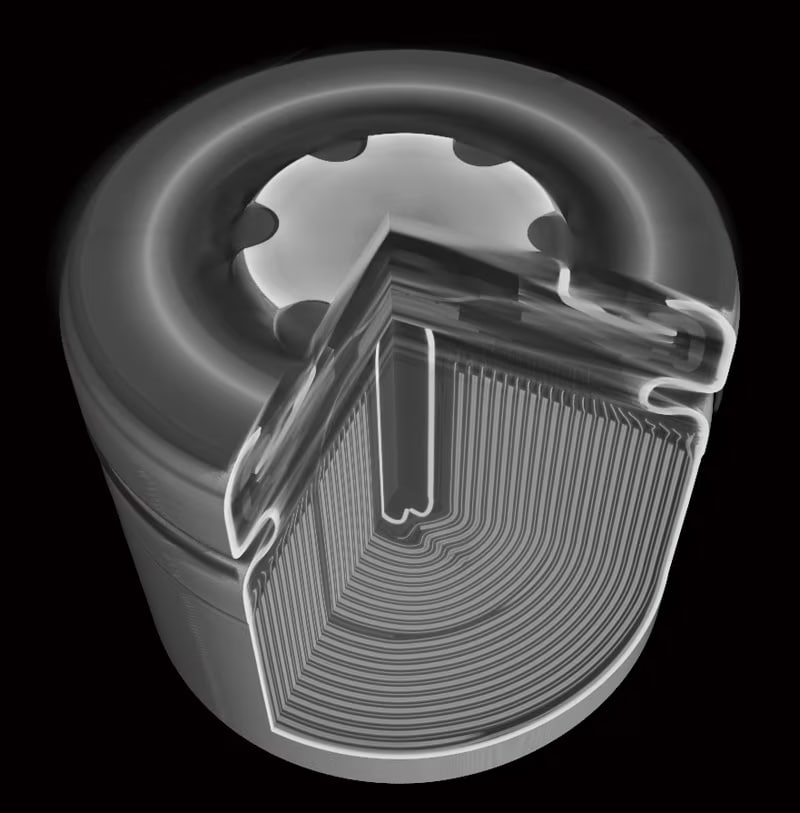

Lithium-Ion Rechargeable Battery

-

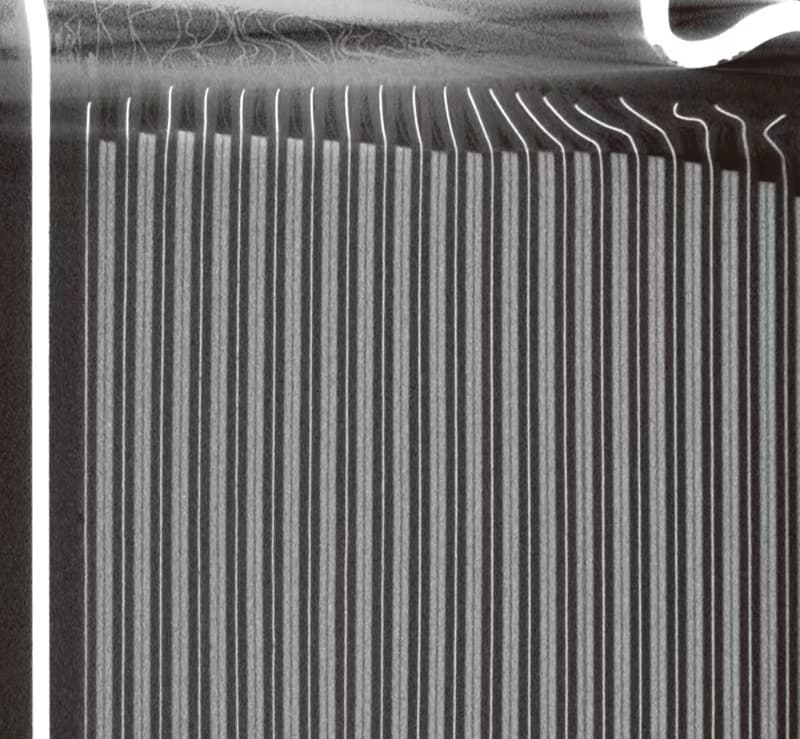

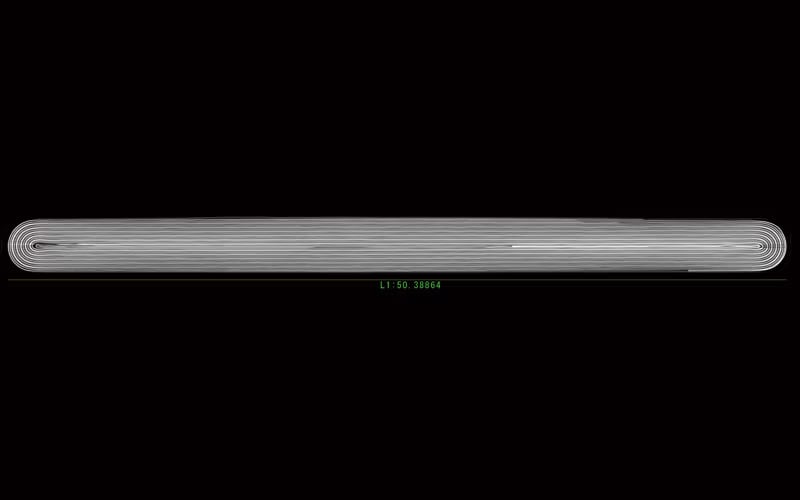

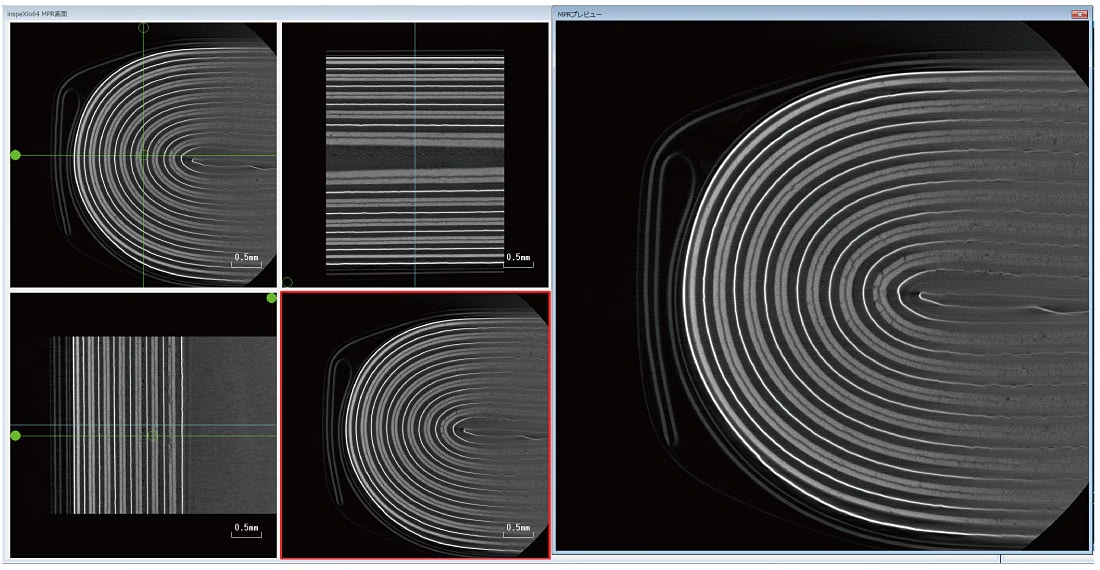

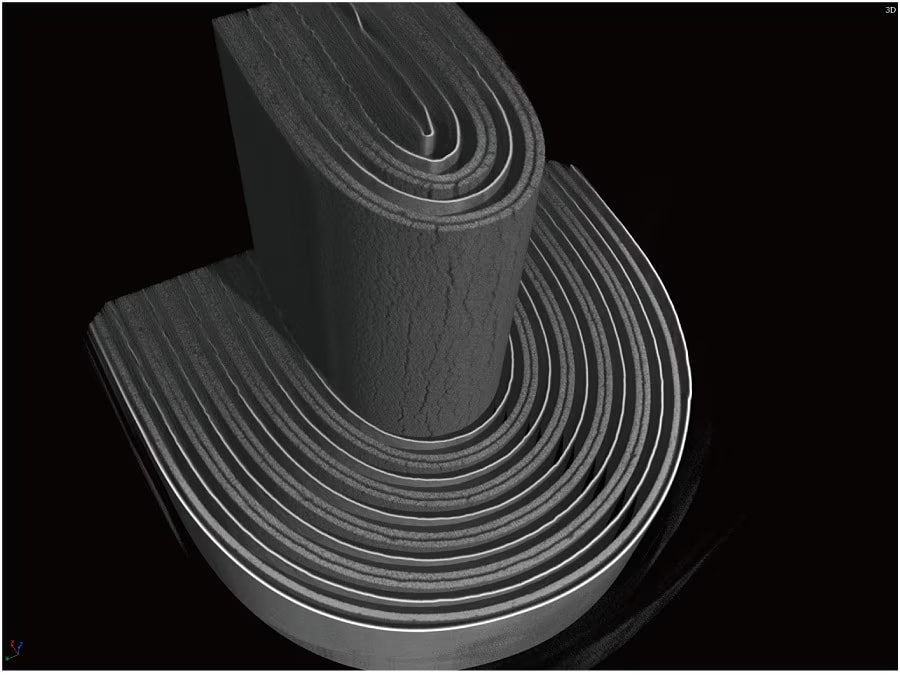

Rectangular Lithium Polymer Battery (for Smartphones)

-

Circuit Board

-

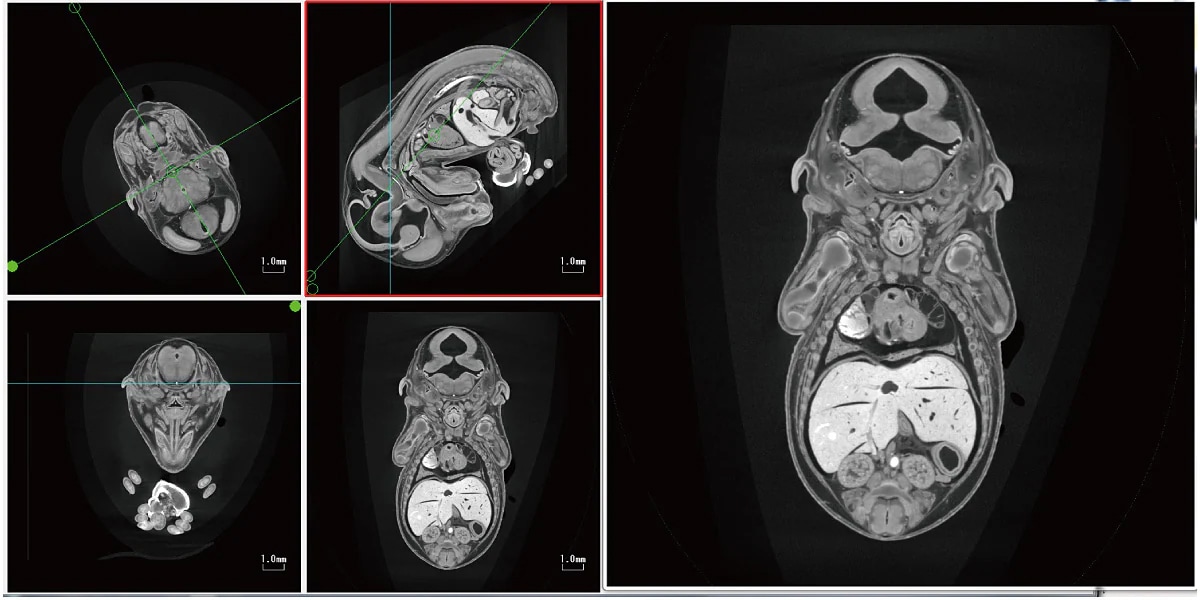

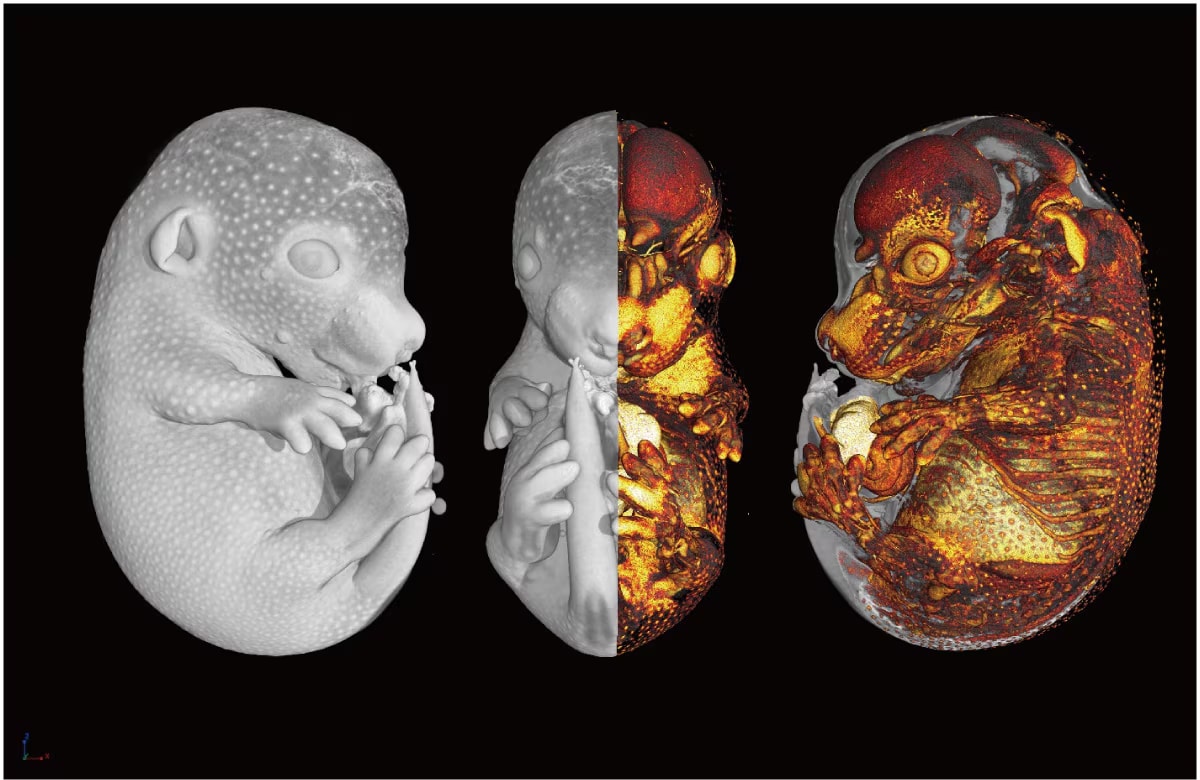

Mouse Fetus

-

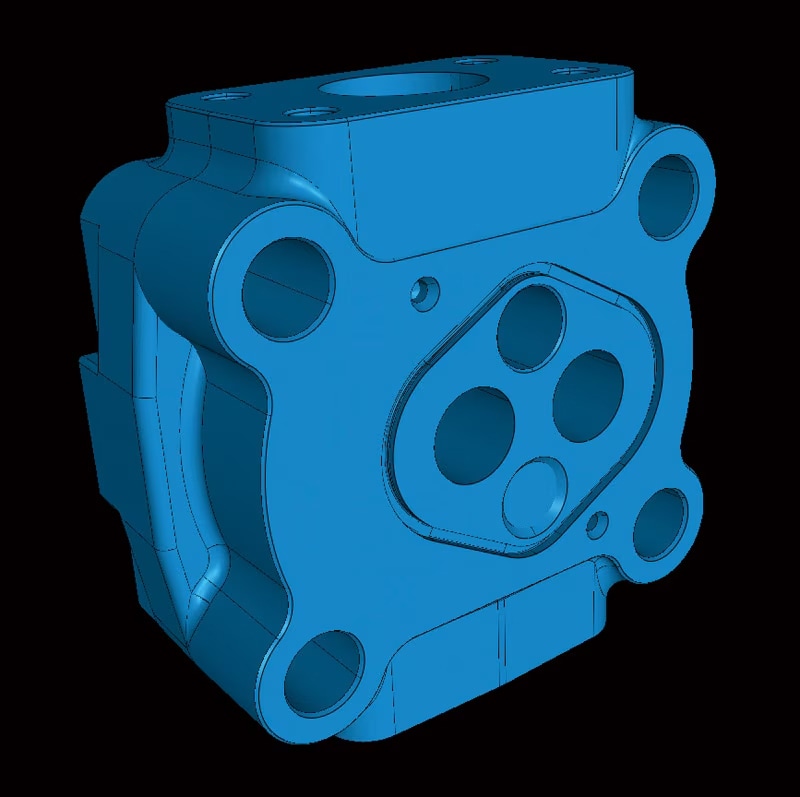

Analysis Using PointMaster Reverse Engineering Software

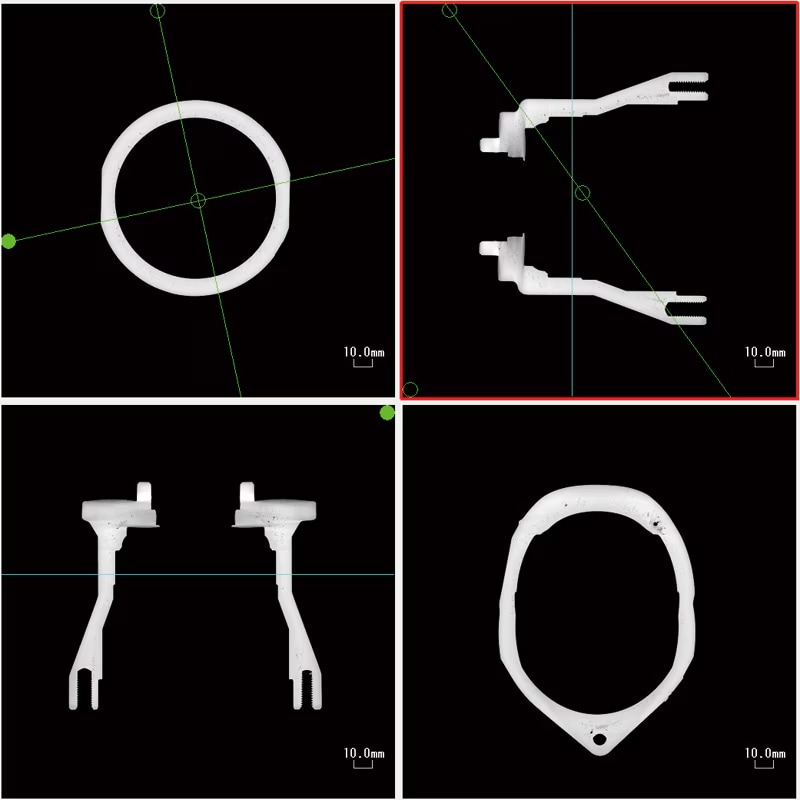

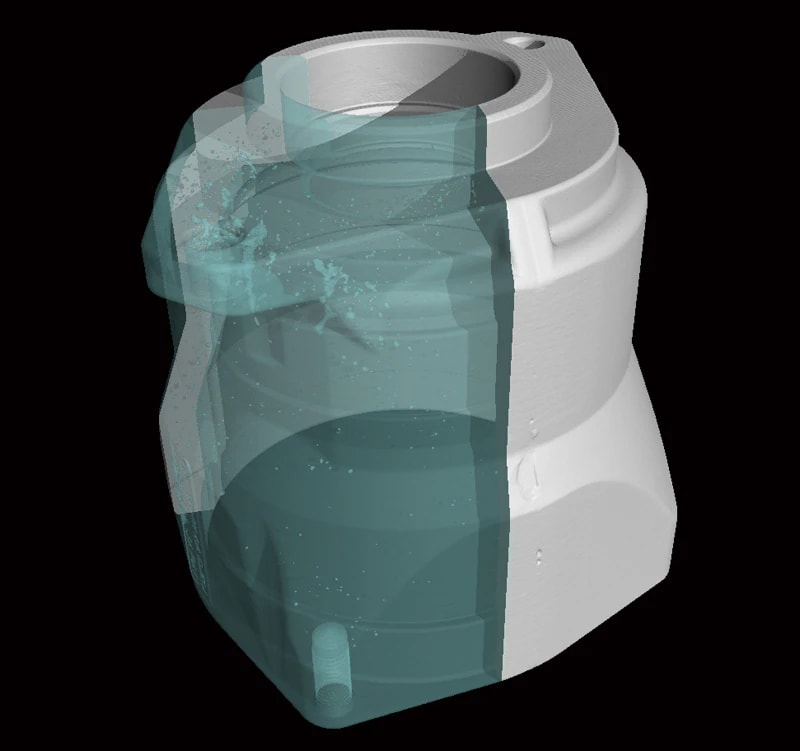

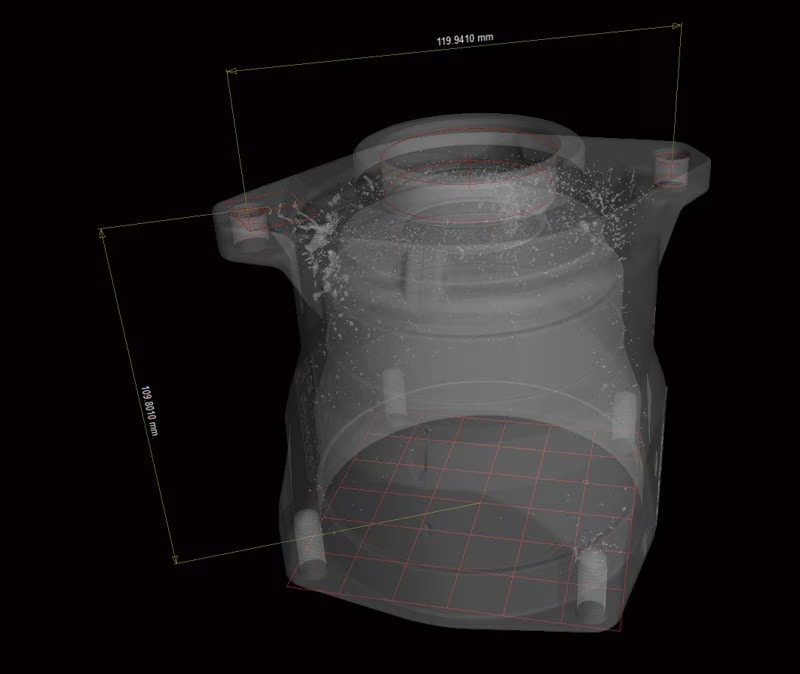

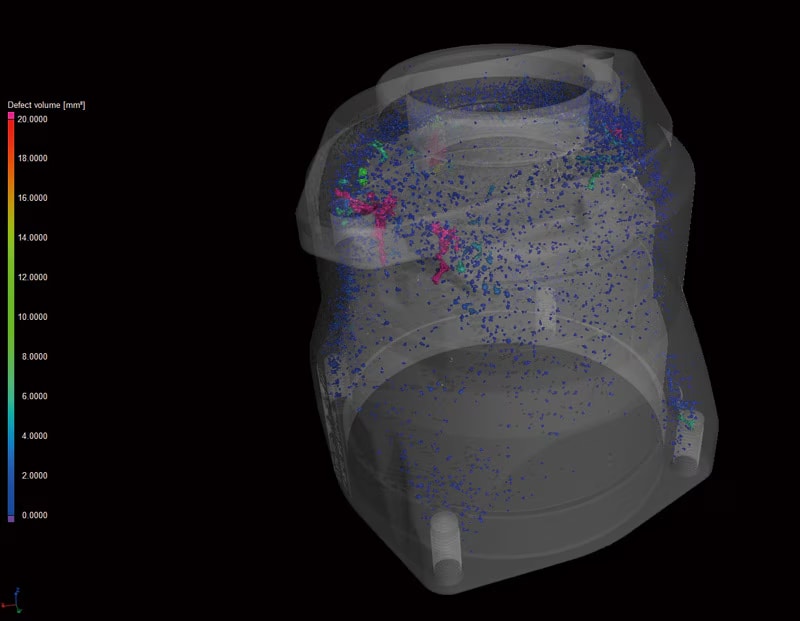

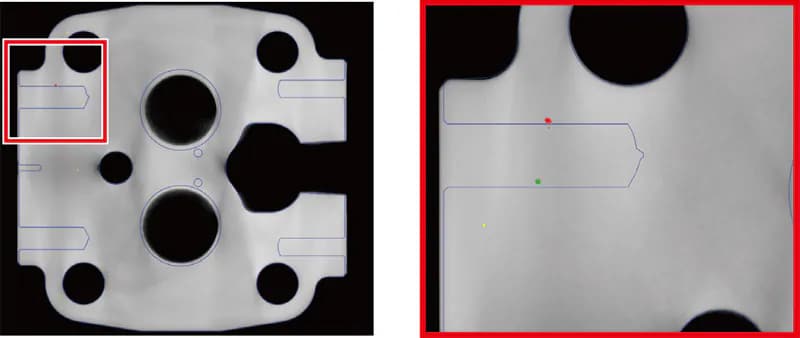

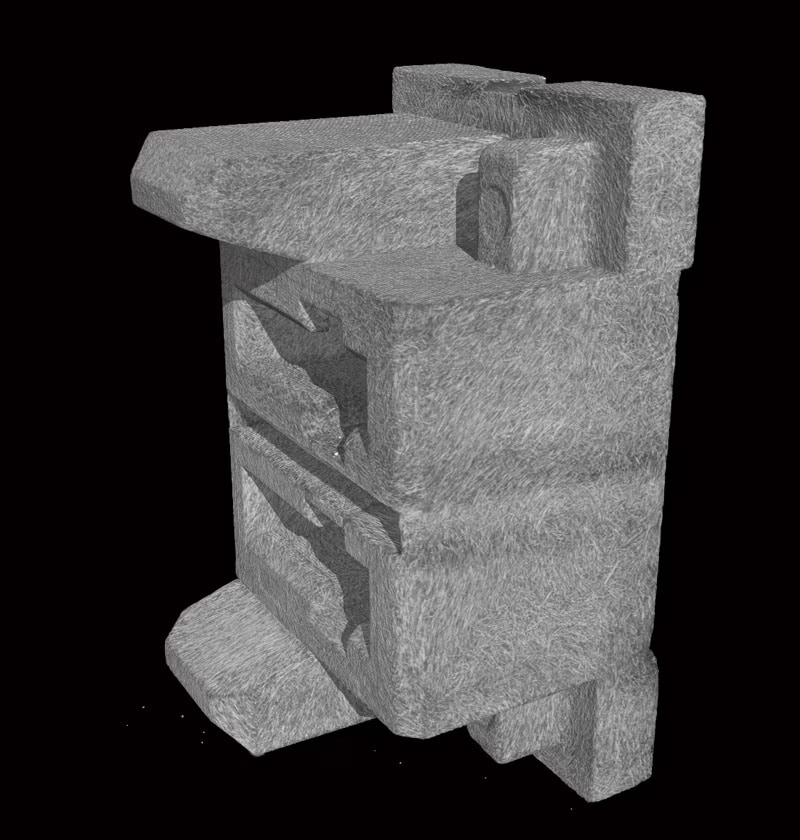

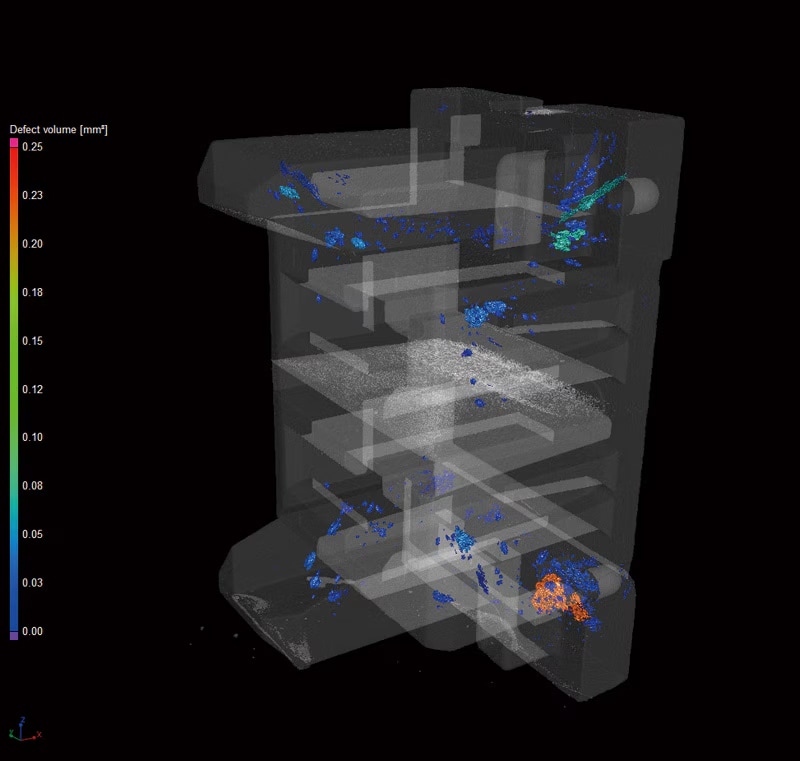

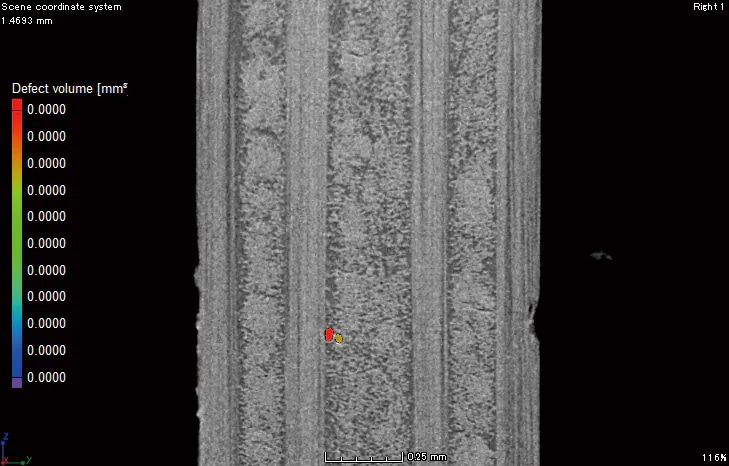

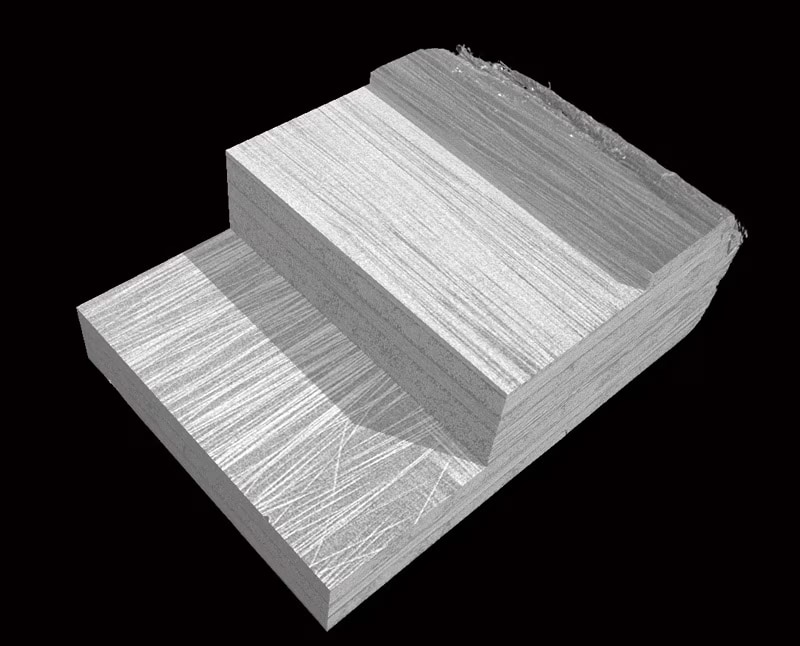

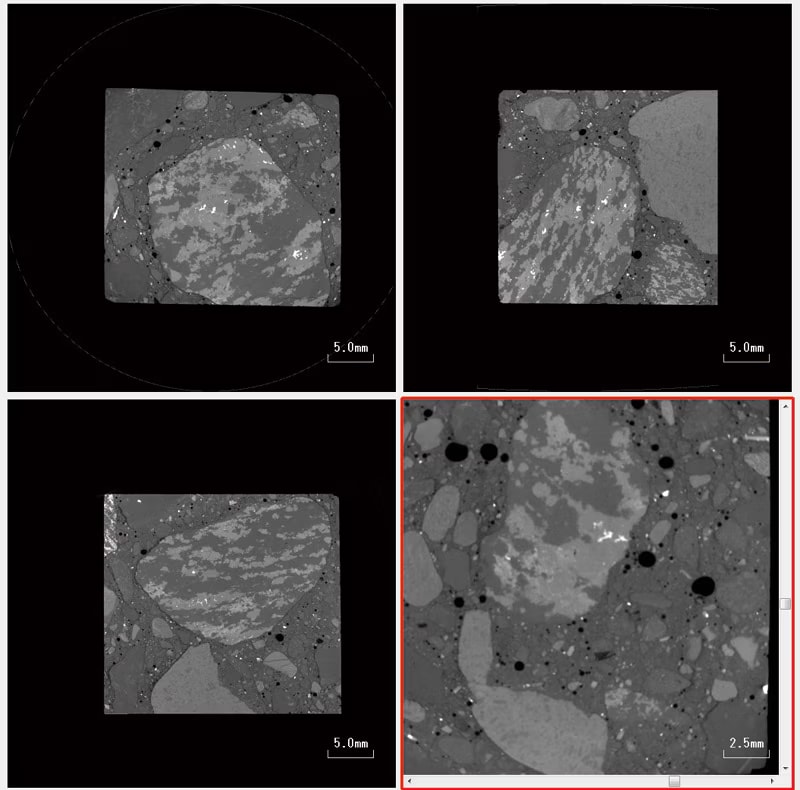

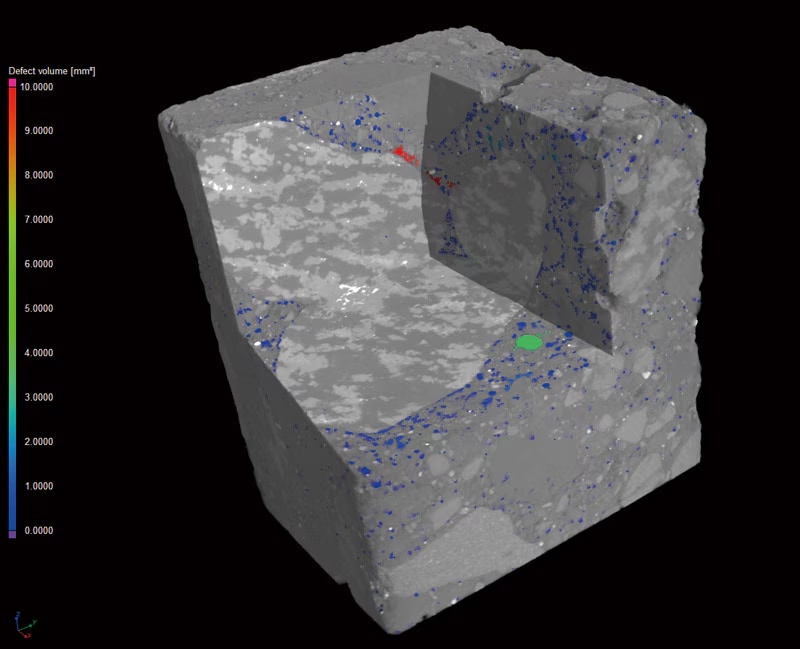

Aluminum Die Castings

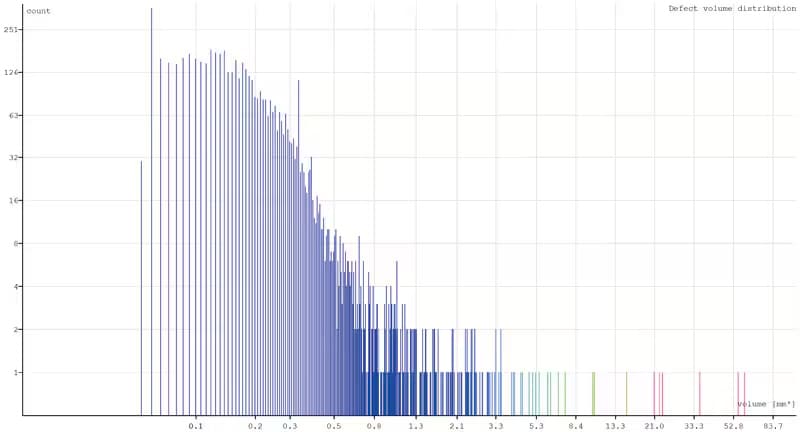

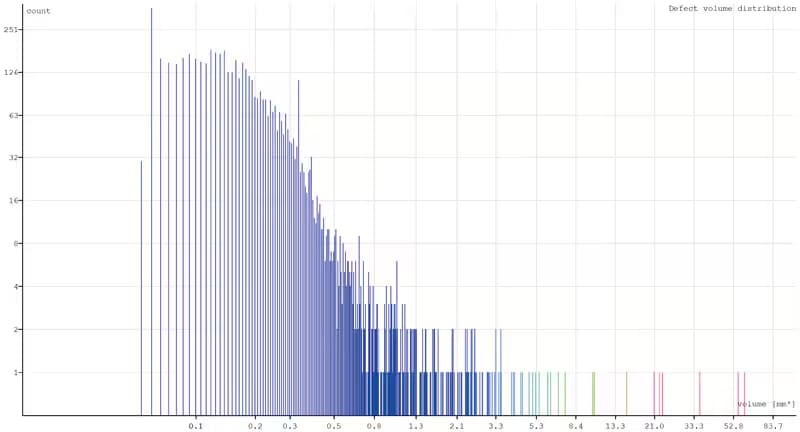

Defect Analysis Histogram

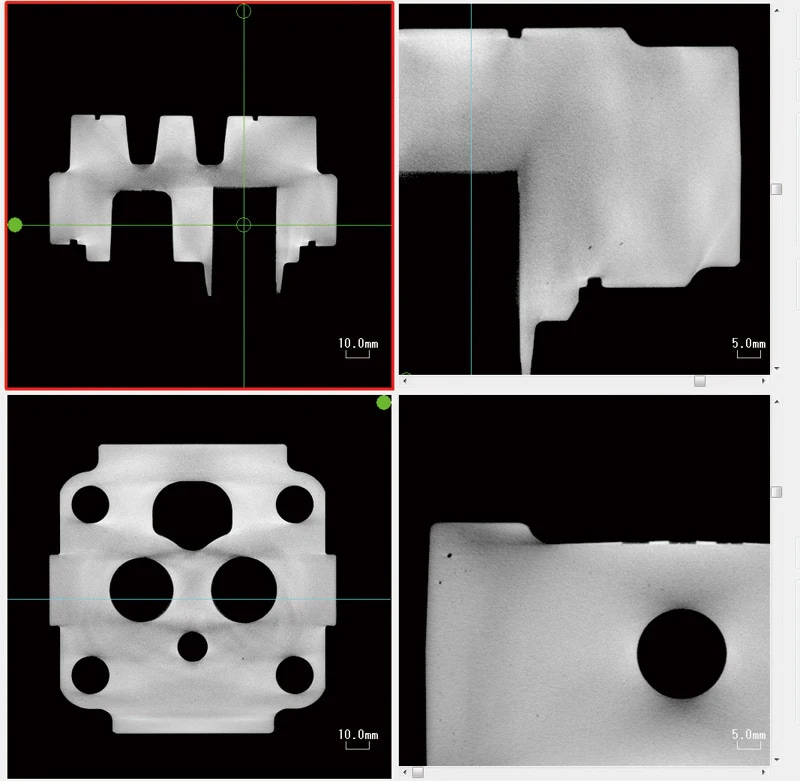

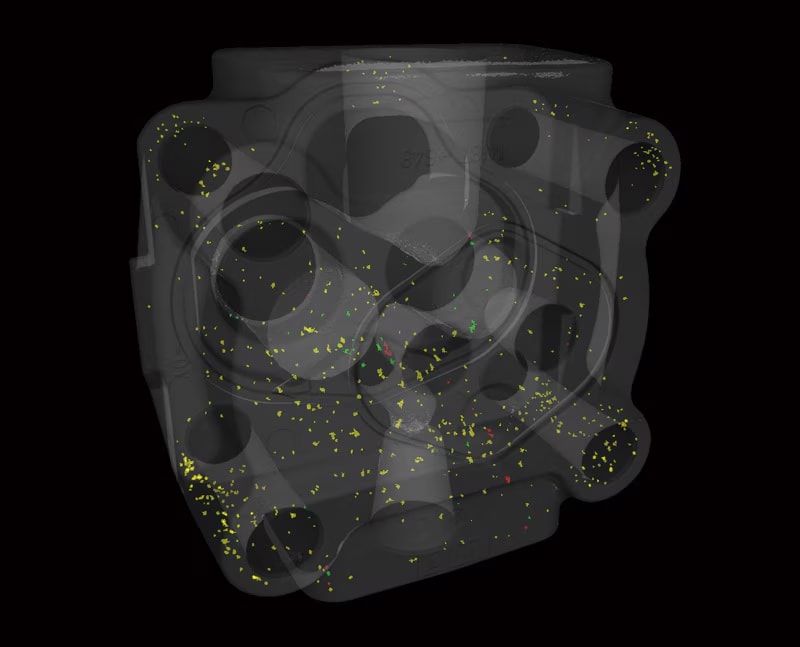

Defect analysis identifies voids and displays a color-coded map of the voids based on their volume. It can also display a frequency histogram of scale the void volume and count.

By scanning the die cast part before machining and then specifying the surface after machining (CAD data), the software can determine which voids are removed by machining, which remain internally, and which are exposed on the surface after machining.

● Voids that are removed

● Internal voids

● Voids exposed on the surface

Blue line: CAD data analysis after machining

GFRP (Glass Fiber Reinforced Plastic)

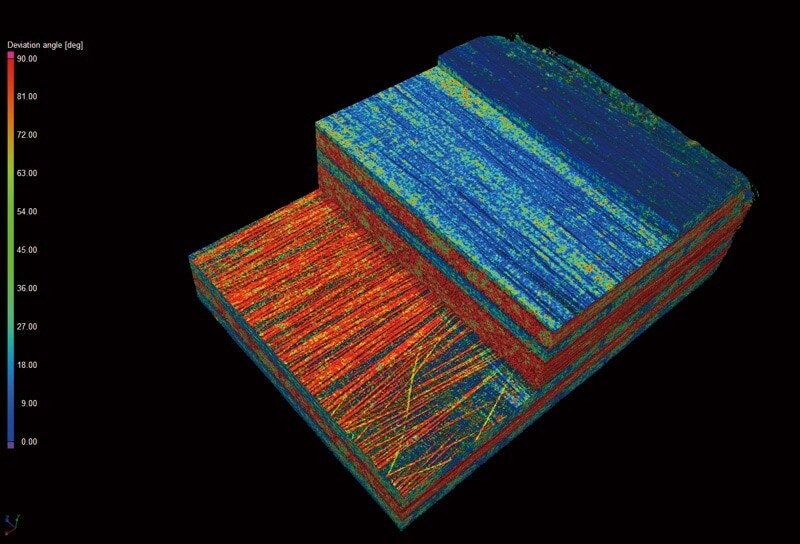

CFRTP (Continuous Fiber Reinforced Thermoplastic Laminate)

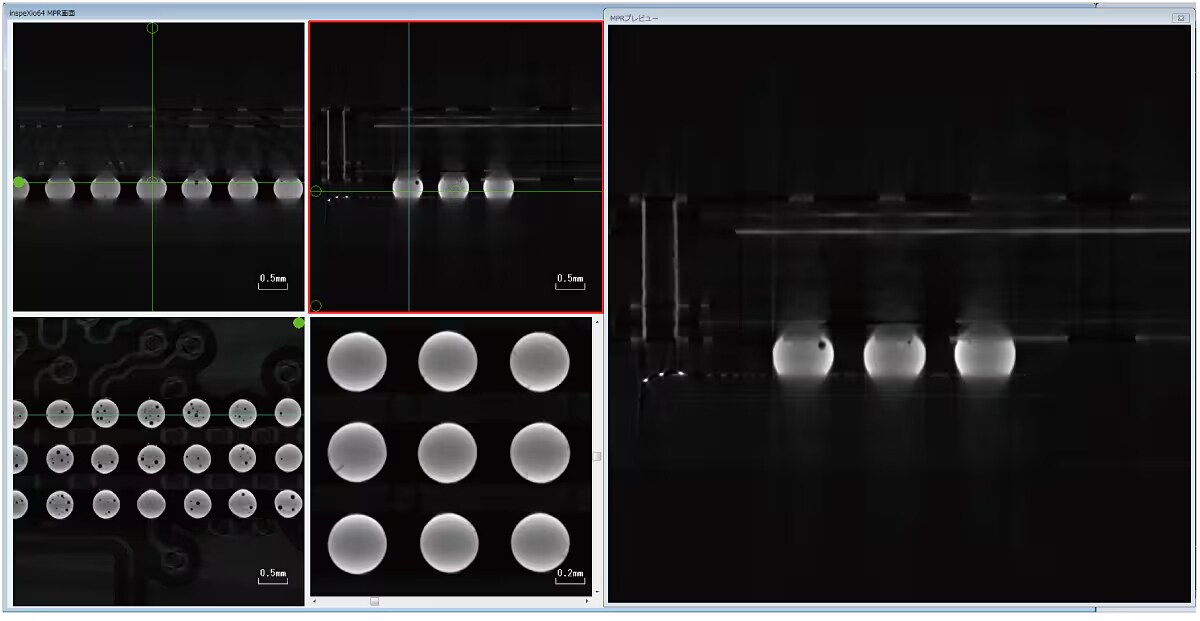

BGA (Ball Grid Array)

Concrete

Lithium-Ion Rechargeable Battery

Rectangular Lithium Polymer Battery (for Smartphones)

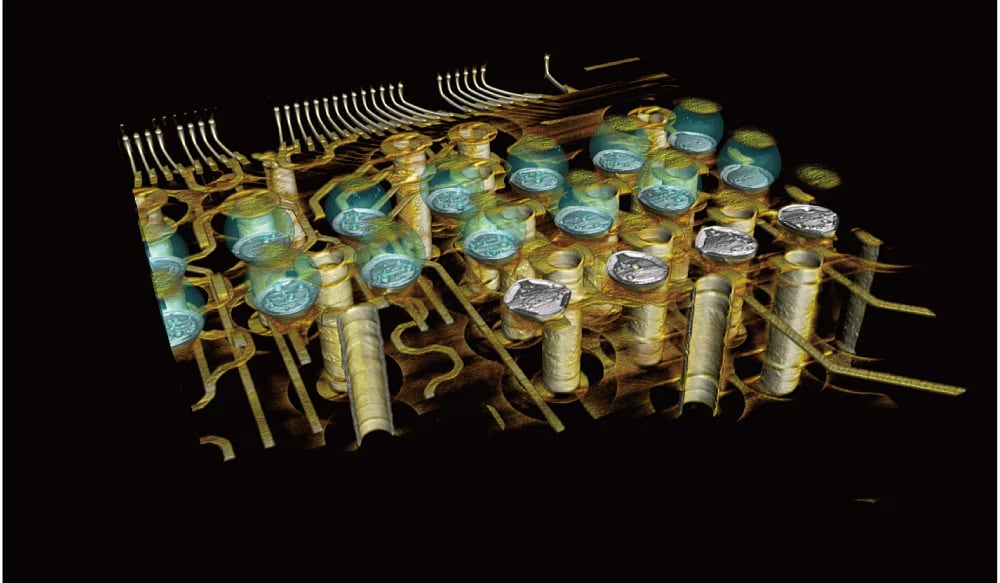

Circuit Board

Mouse Fetus

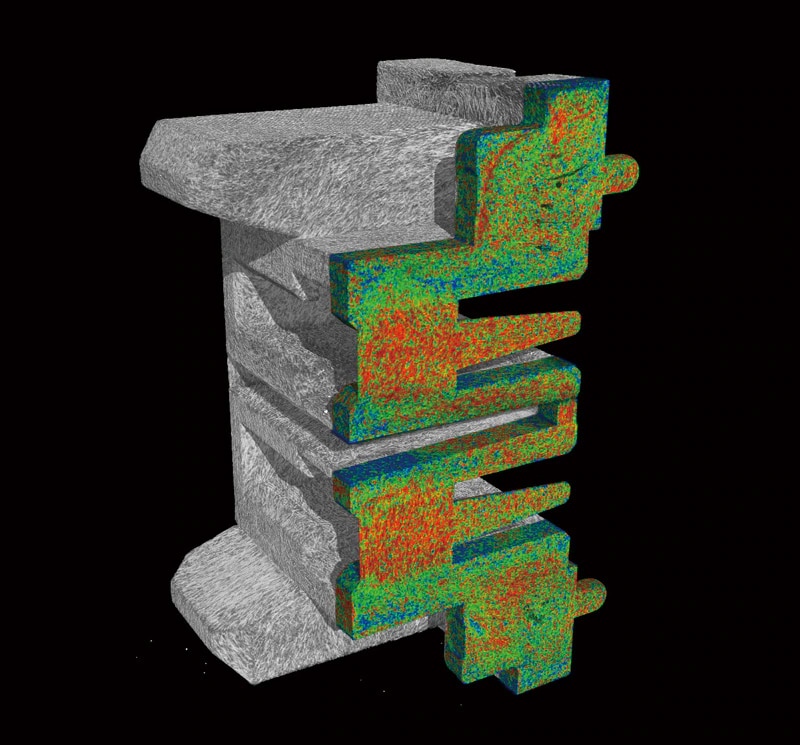

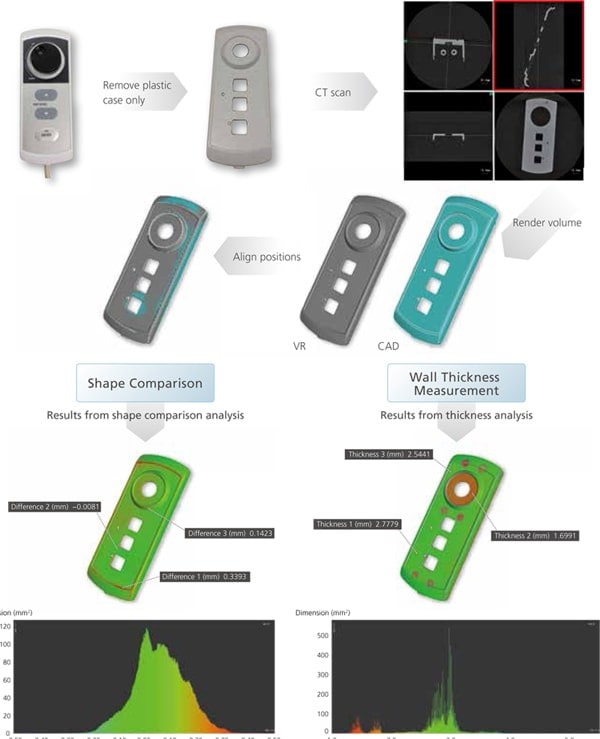

Analysis Using PointMaster Reverse Engineering Software

The software can align CT data with 3D-CAD data, calculate the distance between the boundary surface defined in the CT data and the corresponding 3D-CAD data, and display a color-coded map based on such differences.

For inquiries about the absorbed dose to samples such as semiconductors, please contact here.