AABC (Advanced Automotive Battery Conference) 2025

December 9-11

Caesars Palace

Las Vegas, NV

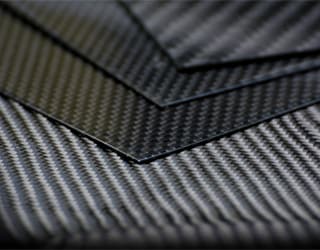

To reduce weight and increase fuel economy, aerospace and automotive designers are increasingly using lightweight composite materials such as carbon fiber reinforced plastics (CFRP). CFRPs offer high strength with reduced weight making them ideal for high-performance applications.

Thorough characterization of composites is essential to ensure effective modeling and safe adoption of these new materials in final products. Shimadzu offers a complete range of characterization tools to evaluate the mechanical and thermal behavior of composites.

Thorough mechanical characterization of new plastics and composites is essential to ensure effective modeling and the safe adoption of these new materials in final products. ASTM standardized test methods for plastics and CFRPs are widely used to evaluate these new materials. This eBook describes the use of Shimadzu’s AGX Series Universal Test Machines to evaluate plastics and CFRPs according to several ASTM methods.

| ASTM Method | Recommended Solution | |

|---|---|---|

| ASTM D5379 | V-Notched Bean Testing (Iosipescu) of CFRP | AGX-V, TRViewX, StrainView |

| ASTM D6484 | Open-Hole Compression (OHC) Testing of CFRP | AGX-V, Compression Plate |

| ASTM D6641 | Combined Loading Compressions (CLC) Testing of CFRP | AGX-V, Compression Plate |

| ASTM D7078 | V-Notched rail Shear Testing of CFRP | AGX-V, TRViewX, StrainView |

| ASTM D638 | Tensile Properties of Plastics | AGX-V, AGS-X, Wedge Grips, Extensometers |

Carbon fiber reinforced plastics (CFRP) have been widely adopted as a material in the latest aircraft and automotive frames. CFRPs are particularly lightweight, possess high specific strength, and are highly corrosion-resistant. Their use is expected to grow in a variety of fields. Particularly in the transportation field, lightweight materials lead to lower fuel consumption, which has a direct connection to reducing environmental load. Research has accelerated in the search for even higher performance materials and processing methods. Shimadzu provides a range of instruments and systems for analysis, testing, and inspection evaluations (from analysis and testing pre-treatment to data analysis), thereby contributing to resolving a variety of problems at each phase, from the development of CFRP raw materials to product durability evaluations.

The image illustrates the breakage of the CFRP by the high-speed tensile testing machine. The CFRP fractures instantaneously at the limit load, so a recording speed of 10 million frames/second is required to capture the fracturing process in detail.

Recording speed: 10 million frames/second

Width of field of view: Approx. 10 mm

Cellulose is the main component of plants. It is also the most abundant carbohydrate on earth and has been used as raw materials of paper and textiles since antiquity. In recent years, cellulose nanofiber (CNF) with higher functionality realized by defibrating cellulose to the nano level has attracted considerable attention. CNF has low environmental impacts, as it is a plant-derived material, and possesses a variety of desirable functions, including low linear expansion, a gas barrier property, and transparency. It is also lightweight, weighing only 1/5 as much as steel, and displays high specific strength 5 to 8 times stronger than ferrous materials. It is essential to clarify not only the static echanical properties of materials, but also their impact properties, fatigue characteristics, and thermal characteristics. In this article, the tensile strength of CNF-reinforced plastic was evaluated at various test speeds (strain rates) by using a Shimadzu testing machine and high-speed impact testing machine. The fracture surfaces of the specimens after the tests were also observed by using an electron probe microanalyzer (EPMA).

Thermoplastic CFRPs utilize resins which soften when heated, and the representative resins used in this type span a wide range, including polyamide (PA), polycarbonate (PC), polyphenylene sulfide (PPS), and others. While the thermoplastic CFRPs are inferior to thermosetting CFRPs in terms of strength and rigidity, their mass producibility is excellent and secondary processing is easy. Moreover, because recycling is possible, production costs can also be held to a comparatively low level. For these reasons, thermoplastic CFRPs have attracted considerable attention as new materials for realizing weight reduction in mass production-type automobiles. Because the resins used in CFRPs can be differentiated easily by analysis by Fourier transform infrared spectrophotometry (FTIR), FTIR is an effective tool for quality control when determining the resin components of CFRPs before recycling. In this article, thermosetting and thermoplastic CFRPs were measured by FTIR and their component resins were differentiated.

In conventional product design development, there was a time when design work was considered complete with only CAE analysis. Today, however, actual measurement

under the same conditions as the CAE analysis model and verification by comparison of those results and the CAE analysis results to validate the appropriateness of

the simulation results (V&V: Verification and Validation) is considered important. As a result, product desig utilizing both actual measurement and CAE analysis is

becoming a general social requirement. This article presents an outline of the distinctive features of composite materials related to CAE analysis, and based thereon, introduces examples of V&V by comparison of the CAE analysis results with the results of actual measurements of a Carbon Fiber Reinforced Thermo Plastics (CFRTP) fabric material.

Fiber reinforced plastics (FRP) have higher mechanical properties per unit weight than metal materials such as steel and aluminum and therefore are used now as substitute materials for metals in a variety of industrial products. Particularly in recent years, high quality carbon fibers, resin-impregnated prepregs containing those fibers, and advanced molding technologies have been developed. As a result, FRP has now gained wide acceptance and has an extensive record of actual use, and is also beginning to be used in main structural parts of aircraft and automobiles, in which high reliability is essential. However, in the case of carbon fiber reinforced plastic (CFRP), which consists of carbon fiber and resin, in combination with the existence of adhesive interfaces, the failure process also has an extremely complex mechanism.

Carbon fiber is an important industrial material, being essential in carbon fiber reinforced plastics (CFRP), having a specific gravity one-fourth that of normal steels, and a specific strength of 7 times. In this Application Data Sheet,

examples of tensile testing of single carbon fibers based on the ISO standard are introduced.