Sub Category

Shimadzu’s instruments are used by scientists throughout the Americas, and we count as customers some of the world’s leading institutions as well as a long list of local, state, and federal government laboratories. In addition, SSI is a leader in the academic community with a robust grant program and a SPARQ (Shimadzu Partnership for Academics, Research, and Quality of Life) program designed to build long-term relationships between the company and colleges/universities.

Shimadzu’s growth throughout its history is a testament to experience, technological expertise and customer service/support. Moving forward, Shimadzu will continue to develop and manufacture instruments that deliver results faster and more efficiently than ever before to meet the needs of researchers, scientists, and manufacturers around the globe.

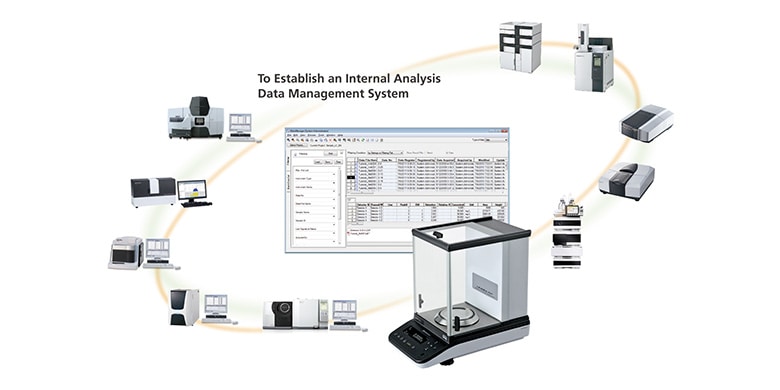

Product Categories

-

-

-

-

-

-

Sub Category

-

-

-

Sub Category

-

Sub Category

-

Sub Category

-

-

-

-

-

-